Home » Separators » SPX FLOW Seital Separators » Dairy Separation

Separation in the Dairy Industry

A key part of the raw milk process is separation. There are many applications in which separation or clarification are essential to the dairy industry. Some applications include:

- Milk skimming

- Whey skimming

- Milk clarification

- Whey clarification

- Milk bacteria clarification

- Automatic and manual standardization

- Cream concentration

- Butter oil production

We have been working within the dairy industry for many years. Therefore, we are uniquely able to support your dairy separation equipment with both new units, spare parts and components, maintenance and full turnkey liquid processing projects.

How it works

Historically, the process of separating fat from raw milk was done by gravity. Raw milk was left in a vessel, and after some time the fat would rise to the surface and be skimmed from the top. Since the introduction of the centrifugal separator, and using centrifugal force to separate fat from raw milk, has changed the dairy industry immensely.

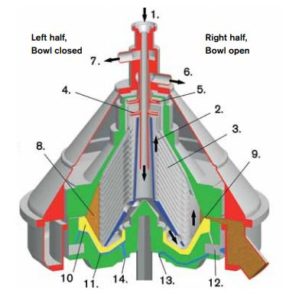

The centrifuge consists of discs stacked together at an angle and separated by a gap or separation channel. Firstly, milk is introduced towards the inner edge of the disc stack. The stack of discs has vertically aligned distribution holes into which the milk is introduced.

Secondly, using centrifugal force, the fat globules move inwards through the separation channels toward the axis of rotation. This is because fat globules are less dense than skimmed milk. Finally, the skimmed milk, now devoid of fat globules, will move outwards and leaves through a separate outlet.

Furthermore, being able to efficiently separate fat from your raw milk product opens up a range of possibilities for product diversification and business growth.

Keeping you processing