Self-cleaning Clarifiers

Self-cleaning clarifiers for liquid/solid separation. The clarifier allows the recovery of fine particles (0.5-500 µm) and/or a strong clarification of liquids by means of a very high peripheral centrifugal field (G-force).

Self-cleaning clarifiers for liquid/solid separation. The clarifier allows the recovery of fine particles (0.5-500 µm) and/or a strong clarification of liquids by means of a very high peripheral centrifugal field (G-force).

How They Work

Clarification

Clarification

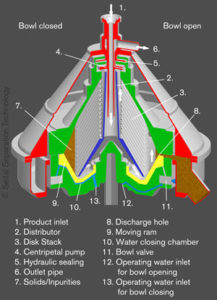

The product to be clarified flows into the bowl through a feed pipe (1) and into the distributor (2) it then undergoes acceleration until it reaches the rotating speed of the bowl. The distributor (2) conveys the product to the disks stack (3) where the clarification takes place. The clarified liquid then rises in the disks stack and reaches the upper chamber of the bowl. Here a fixed centripetal pump (4)conveys it under pressure to the outlet pipeline (6). A hydraulic sealing device (5) prevents product oxidation due to ambient air.

Solids discharge

The separated solids are collected in the peripheral part of the bowl (7) and are periodically discharged through the discharge holes (8). The discharged solids are collected into an outer annular chamber connected to a damping sludge tank where they are drained away by gravity through a pipe. The pressure produced by water in chamber (10) keeps the hydraulically operated ram (9) in a closed position. By feeding water through the pipeline (12), the bowl valve (11) allows the water in the chamber (10) to flow away; the product pressure pushes down the hydraulic ram and the solids are immediately ejected through the discharge holes (8). By stopping the water feed (12) and filling the closing water line (13) into chamber opening (10), the hydraulic ram goes back to the closed position.

Automatic control

The periodic solids discharge is carried out automatically by means of a PLC which controls the opening and closing water solenoid valves and the solenoid valves of the operating water circuit. Various automatic, independent working cycles may be selected to perform partial and/or total discharges during separation and cleaning cycle. By setting the PLC it is possible to adjust the discharged volume, the frequency and the combination between partial and total discharges. The PLC can also perform the following functions: automatic bowl closing during the starting phase; stop feeding during total discharges; rinsing of all internal surfaces, before and after the discharge; manual control of partial and total discharges; bowl overflow (during CIP); product recirculation.

Inlet-outlet flow unit

Inlet-outlet pipelines can be completed with valves and instruments necessary to monitor and control the separation process, with pneumatic valves, micrometric adjusting valves, butterfly valves, check valves, illuminated sight glasses, sanitary manometer, flowmeter, and a turbidity detector, etc.