APV/SPX R Series Rotary Pump

SPX FLOW R Series Rotary Pumps are known all over the world for their rugged, long lasting design and efficient performance. Backed by a worldwide sales, engineering and service organization, R Series Rotary Pumps are designed and built in a modern manufacturing facility using the latest programmable automated machine tools. Each component must meet rigid quality control standards.

SPX FLOW offers an exceptional range of capacities, rotor types, mounting configurations and options. The exclusive resilient rotors form a continuous flexible seal between suction and discharge. Product flow is positive, continuous, non-agitating and completely controlled at all times.

Features and Benefits

- Simple design – few parts

- Ideal for manually cleaned applications – Clean out of Place

- Can be disassembled in few minutes

- Strong structure

- Floating rotors – no shimming required

Theory of Operation

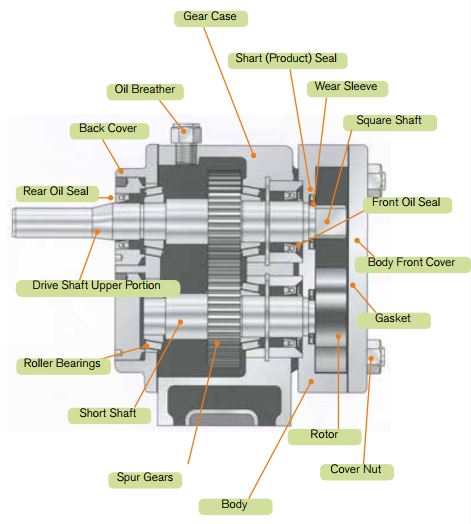

R Series Rotary Pumps incorporate a long life, sanitary, stainless steel body with versatile, resilient, molded rotors and a heavy duty cast iron gear case – all of which are designed to give dependable, economical service over a wide range of products and applications. All product contact parts are 316 stainless steel with food grade seal and rotor materials which will not impart odors or affect flavors. All parts are interchangeable and replaceable in the field.

Typical Product Applications

Beverage:

- Fruit Juice

- Cider and Wine

- Yeast

- Liquid Sugar and Glucose

Food:

- Fruit Preserves

- Soups and Sauces

- Baby Food

- Chocolate

Pharmaceutical and Toiletries:

- Antibiotics

- Toothpaste

- Cough Medicine

- Shampoo

Dairy:

- Cream

- Butter

- Yogurt

- Ice cream

- Cheese Curd & Whey

Chemical:

- Paint

- Oil Additives

- Resins

- Photographic Film Coatings

Product Specifications

| Model Sizes | ||||||||

| 0 | 1 | 2 | 3 and 3 HD | 4 and 4 HD | 5 and 5 HD | 700 HD | ||

| Maximum Capacity* | gmp | 2.5 | 6 | 9 | 5.5 | 145 | 240 | 200 |

| m³/hr | 0.57 | 1.36 | 2.0 | 8.2 | 20.4 | 34.1 | 45.4 | |

| Displacement per 100 revolutions | Gal/100 rev | 0.46 | 1.0 | 1.5 | 6.4 | 17.5 | 29.0 | 58.0 |

| Litre/100 rev | 1.75 | 3.88 | 5.8 | 24.3 | 66.2 | 111 | 220 | |

| Maximum RMP | 600 | 600 | 600 | 900 | 900 | 900 | 400 | |

| Connection Sizes (Standard) | in | 1.5 | 1.5 | 1.5 | 2 | 2 or 3 | 3 | 4 |

| mm | 38 | 38 | 38 | 51 | 51 or 76 | 76 | 102 | |

| Rectangular Inlet (Optional) | in | N/A | N/A | .875 x 2.5 | 1.5 x 4.5 | 1.75 x 9.25 | 3 x 9.25 | 6.625 x 9.25 |

| mm | N/A | N/A | 22 x 63 | 38 x 114 | 44 x 235 | 76 x 235 | 168 x 235 | |

| Maximum Power Requirement** | BHP | 0.5 | 0.9 | 1.5 | 7.5 | 20 | 30 | 20 |

| Kw | 0.37 | 0.67 | 1.2 | 5.6 | 14.9 | 22.4 | 15 | |

| Rotors | Number of lobes | 2 | 5 | 5 | 5 | 5 | 5 and SGL | 5 and SGL |

| Material | R | R | R | R, SE and M | R, SE and M | R, SE and M | R, SE and M | |

* Based on 70°F (21°C) water at 0 psi. R= Rubber SE= Sealed Epoxy M= Metal SGL= Single

**Maximum power requirement increases with product viscosity.

Options and Accessories

Body and Mounting Configurations

- Side Inlet/Outlet is the basic standard design for all size SPX FLOW Rotary Pumps used for pumping light to medium viscosity products.

- Feed Inlets:

- The top feed and top feed-rectangular inlets are used when product is flowing down through outlet tanks or hoppers. The top feed-rectangular configuration is similar to the top feed design but with a large rectangular inlet replacing the standard round connection. The larger inlet accommodates heavy viscous products, or products with large particulates or chunks. Both include a removable pedestal support. The top feed inlet is available in all sizes while the top feed-rectangular inlet is available in pump sizes 2 RI through 700 RI.

- The side feed-rectangular inlet is designed to adopt to the discharge of an auger feed hopper, grinder, blender or specialty hopper and is available in pump sizes 4 RI through 700 RI.

Front Covers

- Standard flat cover for applications up to 100 psi (6.8 bar) discharge pressure.

- Heavy Duty cover contains outboard bearing support to accommodate extended pump shafts for applications with discharge pressures higher than 100 psi (6.8 bar).

- Vented cover is available with manual or pneumatic control and is used to limit maximum discharge pressure at a predetermined setting. Not available on size 0 or heavy duty pumps.

- Degassing/Deaerating cover incorporates relief grooves and manifold to relieve trapped gas/air in viscous products.

- Front Outlet cover replaces bottom outlet normally provided on RI pumps. Allows pump to be used under low height hopper and reduces discharge piping components.

Rotor Exchange Program

SPX FLOW offers a generous exchange program for all SPX FLOW style stainless steel hub rotors, regardless of original manufacturer. In the exchange program, new rubber is molded around a used hub, offering users of SPX FLOW R Series pumps a fast, reliable, cost effective method of replacing stainless steel hub rotors. By reusing otherwise discarded materials, users also help the environment.

- The exchange program benefits include:

- Genuine replacement rotors protect your pump warranty

- Fast turnaround direct from stock inventory

- Savings up to 30% on each reusable rotor

- Savings of 10% on a new rotor if the returned rotor is unusable

- 100% factory inspection of all returned rotors

Configurations

Precision molded and machined rotors have been the heart of the SPX FLOW R Series Rotary Pump for more than 50 years. They are

performance proven and are available in a variety of designs to meet specific application requirements. All SPX FLOW rotors meet all FDA requirements.

- Standard 5-Lobe with recessed faces is provided on all pump sizes 1, 2, 3, 4, 6 and 700. These exclusive SPX FLOW formulated resilient covered rotors are recommended for most applications. Normal size up to 150°F (65°C), under size up to 300°F (149°C).

- Flush Face is the same specification as standard 5-lobe except the faces are smooth (flush), not recessed. Available for pump sizes 2, 3, 4, 6 and 700. Used with abrasive or clinging products that might clog recessed face. Also used in degassing/deaerating pumps with front outlet covers. Normal size up to 150°F (65°C), under size up to 300°F (149°C).

- Single Lobe with recessed faces are available for pump sizes 6 and 700, same displacement as 5-lobe. Used with delicate or fragile products and large particulates or chunks. Normal size up to 150°F (65°C), under size up to 300°F (149°C). Recommended operating limitations; 200 rpm maximum, 100 psi (6.8 bar) maximum.

Seal-Materials

- SPX FLOW offers four different seal options for the R Series pump. All seals have color coded dots for easy recognition:

- Nitrile (Red)

- EPDM (Orange)

- FKM (Blue)

- Neoprene (Green)

- All Seals are lip style seals