Alfa Laval Unique SSV Two Step

The Unique Single Seat Two Step valve meets the highest demands of your process in terms of hygiene and safety. Built on the well-proven Unique SSV platform it can be used for reducing pressure hammersand dosing e.g. in connection with filling of a vessel where an exact volume is required. The degree of opening for the intermediate position can be adjusted by removing spacer rings inside the actuator. Unique Single Seat Valve – Two Step as Change over (NC and NO) can be

used for drainage of two pipes simultaneously or in closing/filling applications.

Working principle

The valve is a pneumatic seat valve in a hygienic and modular design remote-controlled by means of compressed air. It has few and simple moveable parts which results in a very reliable valve and low maintenance cost.

Standard design

The Unique SSV Two Step valve comes in a one or two body configuration. With its module built structure it is designed for flexibility and easy customization through the electronic configurator. The valve features an optimized life span of the seals through a defined compression design. The actuator is connected to the valve body using a yoke and all components are assembled with clamp rings.

Technical Data

Temperature

Temperature range . . . . . . . . . . . . . -10°C to +140°C (EPDM)

Pressure

Max. product pressure . . . . . . . . . . 1000 kPa (10 bar)

Min. product pressure . . . . . . . . . . . Full vacuum

Air pressure . . . . . . . . . . . . . . . . . . 500 to 700 kPa (5 to 7 bar)

Valve Body Combinations

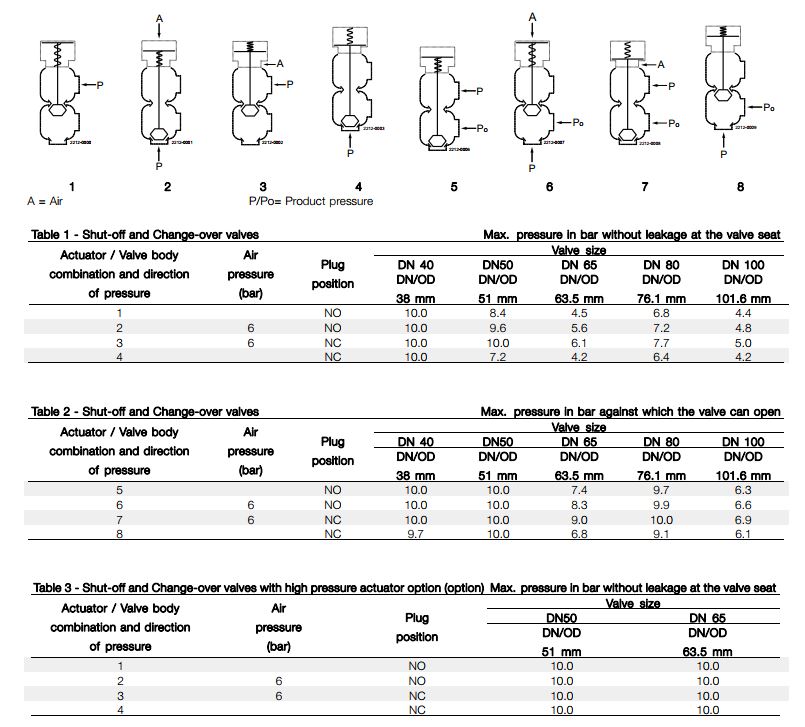

(IMAGE; Diagram)

Actuator function

– Pneumatic downward movement, spring return.

– Pneumatic upward movement, spring return.

Physical Data

Materials

Product wetted steel parts: . . . . . . . . 1.4404 (316L)

Other steel parts: . . . . . . . . . . . . . . 1.4301 (304)

External surface finish . . . . . . . . . . . Semi-bright (blasted)

Internal surface finish . . . . . . . . . . . . Bright (polished), Ra < 0.8 µm

Other product wetted seals: . . . . . . . EPDM

Other seals: . . . . . . . . . . . . . . . . . . NBR

Options

A. Male parts or clamp liners in accordance with the required standard.

B. Control and Indication: IndiTop, ThinkTop or ThinkTop Basic.

C. Product wetted seals in HNBR or FPM.

D. Plug seals HNBR, FPM or TR2 plug (floating PTFE design).

E. High pressure actuator (only ISO51, ISO63.5 and DN50, DN65).

F. External surface finish bright.

Note!

For further details, see instruction ESE00505.

Other valves in the same basic design

The valve range includes several purpose built valves. Below are some of the valve models available, though please use the Alfa Laval computer aided selection tool (Anytime configurator) for full access to all models and options.

– Aseptic valve.

– Tank Outlet valve.

The actuator comes with a 5 years warranty

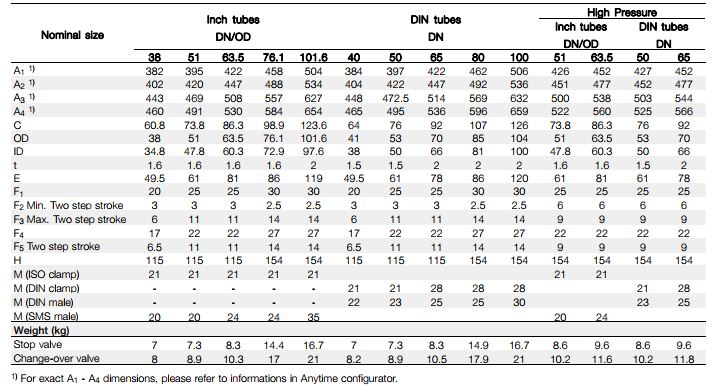

Dimensions (mm)

Air Connections:

R 1/8″ (BSP), internal thread.

Please note!

Opening/closing time will be affected by the following:

– The air supply (air pressure).

– The length and dimensions of the air hoses.

– The number of valves connected to the same air hose.

– Use of a single solenoid valve for serial connected air actuator functions.

– Product pressure.

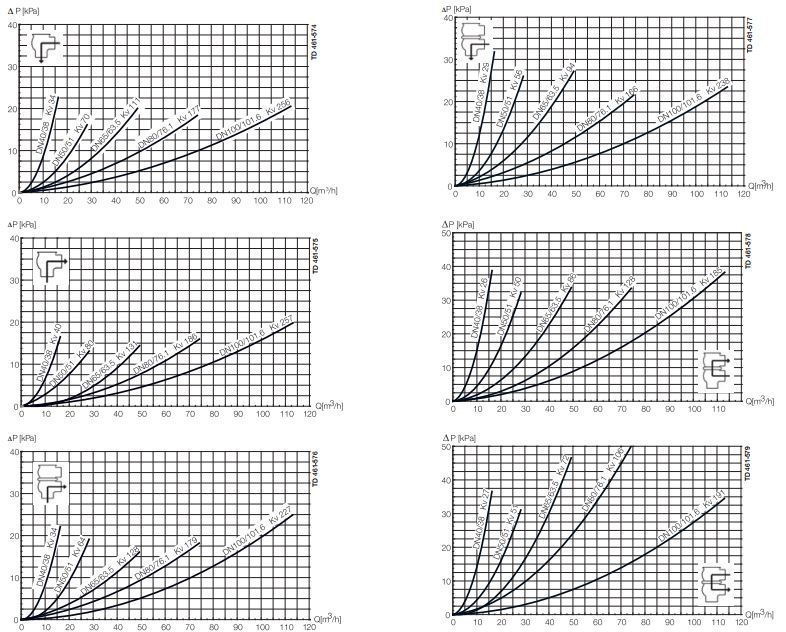

Pressure drop/capacity diagrams

Note!

For the diagrams the following applies:

Medium: Water (20°C)

Measurement: In accordance with VDI 2173

Pressure drop can also be calculated in Anytime configurator.

Pressure drop can also be calculated with the following formula:

Q = Kv x √∆p

Where

Q = Flow in m3/h.

Kv = m3/h at a pressure drop of 1 bar (see table above).

∆ p = Pressure drop in bar over the valve.

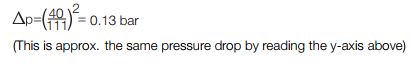

How to calculate the pressure drop for an ISO 2.5″ shut-off valve if the flow is 40 m3/h 2.5″ shut-off valve, where Kv = 111 (See table above).

Q = Kv x √∆p

40 = 111 x √∆p

Pressure data for Unique Single Seat Valve Two Step