Alfa Laval SCPP 1 Circumferential Piston Pump

The SCPP range of positive displacement pumps has been designed for use in a wide range of applications within: Dairy, Food, Beverage, Pharma and Personal Care markets. The highly efficient design is particularly suited to applications that are low in viscosity with medium to high discharge pressures.

Standard Design

Pump Gearbox

The SCPP pump with its circumferential piston pump design concept has a cast iron gearbox which provides maximum shaft ridgity. Gear box is powder-coated. Stainless steel gear box is optional on models 006, 015, 018, 030, 045, 060 & 130. One-piece 316L stainless steel shafts are standard on models 006, 015 & 018. High-strength 17-4 PH one-piece shafts are standard on models 030, 045, 060, 130, 220 & 320. Four-way mounting allows horizontal or vertical porting and provides mounting flexibility.

Pumphead Construction

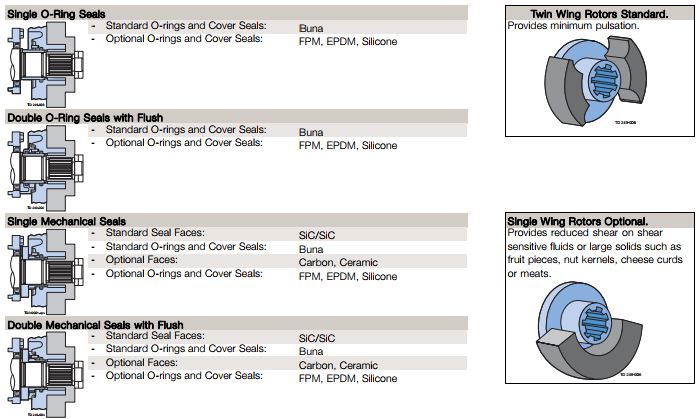

The SCPP in standard specification has pump casing in AISI 316 stainless steel with an internal surface finish of Ra 32/Ra 0.8 complying to 3A standards. Rotors are made of special non-galling alloy and are available as standard with twin-wing form or optionally with single wing for handling large solids. Seal options include single O-ring seal, single mechanical seal, double O-ring seal with flush, or double mechanical seal with flush.

Hot clearances required for high temperature operation.

Materials of Construction

Pump gearbox – high quality grey cast iron. Pumphead – product wetted components in 316L and rotors in special non-galling material. Product wetted elastomers EPDM, NBR, FPM all FDA conforming.

Shaft Sealing Options

…for different liquids and conditions of service

Alfa Laval Positive Displacement Circumferential Piston Pumping Principle

Alfa Laval rotor wings (pistons) rotate around the circumference of the channel in the pump casing. This continuously generates a partial vacuum at the suction port as the rotors unmesh, causing fluid to enter the pump. The fluid is transported around the channel by the rotor wings, and is displaced as the rotor wings re-mesh, generating pressure at the discharge port. Direction of flow is reversible.

Unique Cleaning and Maintenance Features

- Designed for easy strip cleaning, the pump casing is independently fastened to the gearbox to prevent damage to the seals when the cover is removed, and to allow the rotors to be turned while spraying down the fluid chamber

- Bearing retainers are stainless steel, not carbon steel, ensuring longer life under harsh cleaning conditions.

- Grease fittings are threaded, not pressed in, to prevent accidental removal during greasing.

Dimensions