Home » Alfa Laval Spare Parts & Components » Alfa Laval Process Pumps »

Pump Condition Monitoring with Clariot® by Alfa Laval

Supplied and Supported by Moody Direct – UK Master Distributor

Predictive Pump Monitoring for the Food, Beverage, Dairy & Brewing Industries

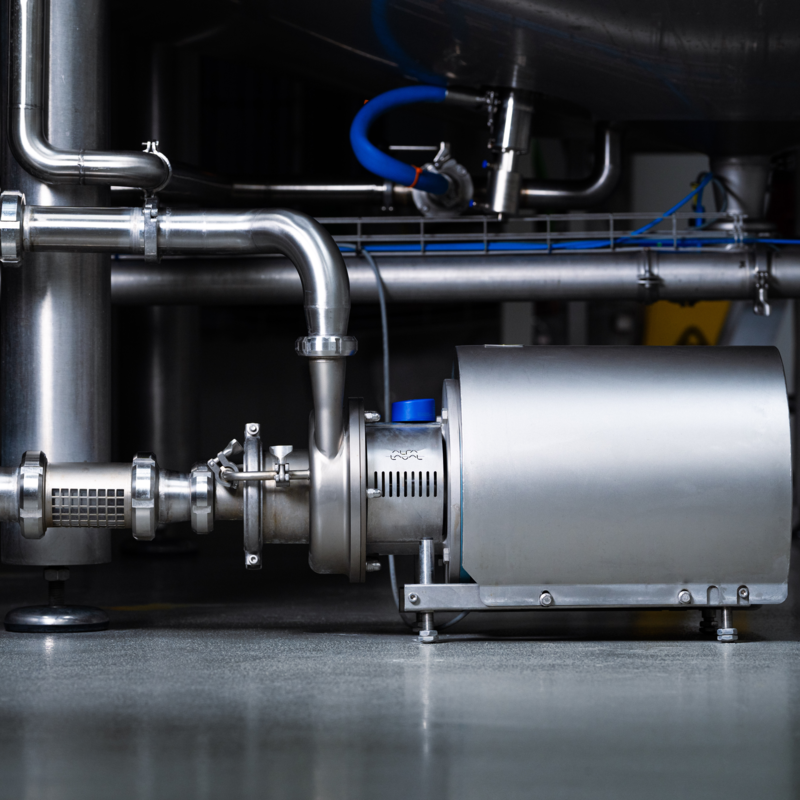

In hygienic processing environments, unplanned pump failures can lead to costly downtime, product loss and contamination risks. Clariot by Alfa Laval is a state-of-the-art pump condition monitoring system that gives you full visibility of your pump performance, enabling you to detect early signs of wear before failure occurs.

As Alfa Laval’s Master Distributor in the UK, we provide complete supply, installation and support for Clariot, helping you safeguard pump reliability and maximise production uptime.

What is Pump Condition Monitoring?

Pump condition monitoring is the continuous analysis of a pump’s health using digital sensors to identify vibration anomalies, temperature changes and performance trends. Rather than waiting for a breakdown, Clariot uses predictive maintenance technology to alert you to issues early, enabling planned intervention with minimal production impact.

Key Benefits:

- Reduce unplanned downtime

- Prevent batch losses and product waste

- Improve energy efficiency and pump performance

- Extend pump lifespan and reduce maintenance costs

- Comply with hygiene and safety requirements

Why Clariot is the Leading Pump Condition Monitoring Solution

Clariot is designed specifically for hygienic industries and rotating equipment used in food, beverage, dairy and brewing processing.

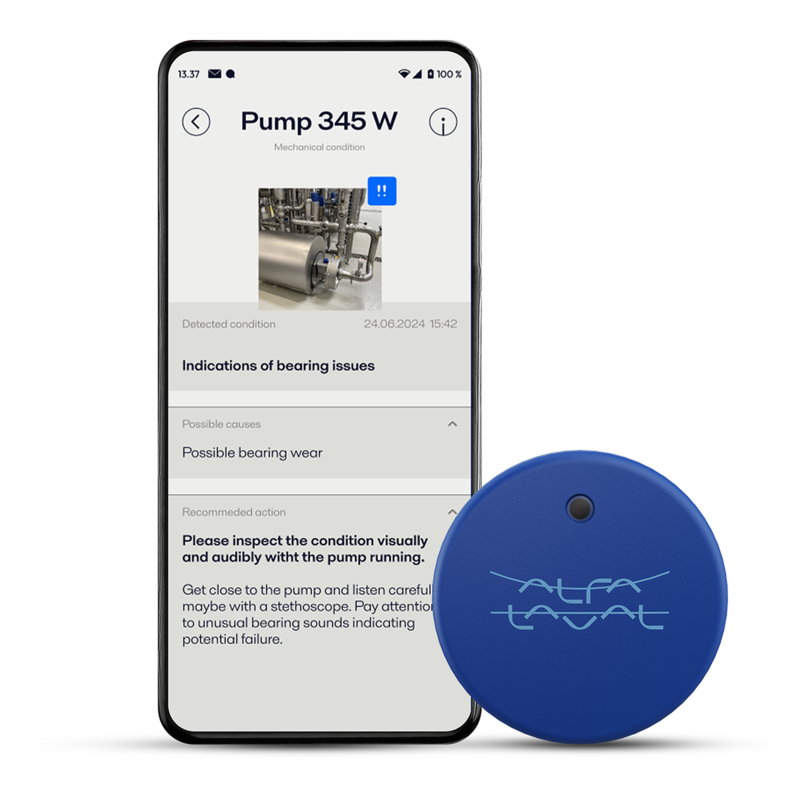

24/7 Digital Monitoring: Real-time pump health insights accessible via desktop or mobile.

Predictive Maintenance Alerts: Receive automatic notifications before pump failure occurs.

Fast, Non-Invasive Installation: Wireless VX™ sensors can be fitted without halting production.

Tailored for Hygienic Pumps: Optimised analytics for centrifugal pumps, rotary lobe pumps and other Alfa Laval fluid handling equipment.

How the Clariot System Works

1. Sensor Monitoring

Clariot VX™ sensors measure vibration, temperature and runtime directly from your pumps.

2. Data Transmission

The Clariot Connect™ gateway sends secure data to the cloud for analysis.

3. Predictive Analytics & Actionable Insights

The cloud-based platform identifies patterns that indicate bearing wear, misalignment, cavitation or imbalance. Maintenance teams receive clear guidance on when and where intervention is required.

Designed for Hygienic Processing Industries

Dairy Industry: Protect high-value pumps handling raw milk, whey and cream – avoid contamination and loss of product due to sudden failure.

Brewing & Beverage: Secure uptime across brewhouses, filtration and bottling plants where pump reliability directly impacts throughput.

Food Processing: Ensure continuous production and reduce cleaning cycle disruptions with condition-based pump monitoring.

Hygienic Fluids & CIP Systems: Monitor pumps critical to cleaning cycles and product transfer—maintaining hygiene standards while reducing energy usage.

Why Choose Moody Direct?

As the UK’s Alfa Laval Master Distributor, Moody Direct provides more than just supply. We deliver:

Genuine Alfa Laval equipment

Genuine Alfa Laval equipment

Experienced pump specialists for site assessment and commissioning

Experienced pump specialists for site assessment and commissioning

UK-wide support and proactive service packages

UK-wide support and proactive service packages

Integration with existing Alfa Laval hygienic process systems

Integration with existing Alfa Laval hygienic process systems

With over 50 years of experience, we are trusted across the food and beverage industries for delivering efficiency, reliability and performance in pump systems.

Get Started with Pump Condition Monitoring Today

Clariot makes the transition from reactive to predictive maintenance simple, scalable and cost-effective. Whether you are managing a single production line or multiple processing sites, Clariot delivers the insight you need to protect your pumps, reduce downtime and increase productivity.

Call: 01777 701141

Email: sales@moodydirect.com

Request a Clariot demonstration or site assessment today.

Moody Direct – Your Trusted Partner for Predictive Pump Performance.