Alfa Laval PX 115 & PX 115EX

The Alfa Laval range of centrifuges for the vegetable oil and animal fat refining industries is continuously modernized to take advantage of developments in materials, mechanical design and fluid dynamics. The PX 115/115EX is a large-sized machine in this range of centrifuges.

Applications

Continuous degumming, neutralizing, dewaxing, and washing of fatty oils, such as various vegetable oils, lard, tallow, and fish oil.

Standard design

The machine consists of a frame with a base that contains a horizontal drive shaft, worm gear, lubricating oil bath and the hollow vertical bowl spindle. The bowl is fixed on top of the spindle inside the space formed by the upper part of the frame, the solids collecting cover and the frame hood. The hood carries the liquid discharge system. All parts in contact with the process liquid are made of stainless steel. The bowl is of the solids-ejecting type with an automatic hydraulic operating system for intermittent solids discharge. The standard electric motor is suitable for variable frequency drive

Design features

The PX 115/115EX is based on a unique, semi-hermetic design concept. The hermetic, bottom-fed inlet ensures a gentle, non-destructive acceleration of the feedstock up to full bowl speed.

The flow area for the feedstock is designed to minimize inlet pressure drop. The outlets on the heavy and light phases are open, reducing the pressure drop across the separator. The feed pressure requirement of the machine is therefore low. The outlets are equipped with stationary paring devices for removal of the different phases. The paring disc on the light phases is fixed, while the paring tubes on the heavy phase are adjustable.

By adjusting a positioner on the heavy-phase outlet, the operator can reduce or extend the paring diameter of the paring tubes. This patented innovation makes it possible to adjust the flow rate of the heavy phase during operation, facilitating optimal separation. With the working environment in mind, the PX 115/115EX is designed to operate at low noise levels. This is achieved through a rubber-damped bearing assembly, jacketed frame and an outer bowl design, which is engineered for low wind noise.

Basic executions

PX 115 for non-explosive environments.

PX 115EX for ATEX zone 2.

Standard equipment

Each PX 115/115EX comes complete with control unit, electric motor, inlet and outlet connections, auxiliary equipment, a spare parts kit and set of tools.

Operating principles

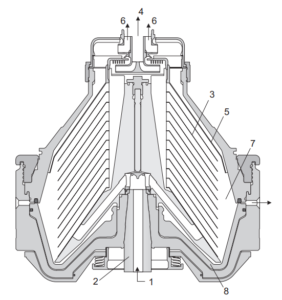

The oil to be separated is fed (1) into the separator bowl from the bottom through a hollow spindle (2) and enters the disc stack (3). The heavy phase and heavy sludge are forced towards the periphery of the bowl, while the light phase flows towards the centre of the bowl, from where it is pumped out (4) for further processing. The heavy phase is led over a top disc (5) into a chamber where an adjustable paring device pumps it out of the separator (6). Sludge collects in the sludge space (7) and is discharged intermittently and automatically. The discharge is achieved by a hydraulic system which at preset suitable intervals forces the sliding bowl bottom (8) to drop down, thus opening the sludge ports at the bowl periphery. The sludge is collected in the frame and leaves the centrifuge via a cyclone.

Material data

| Bowl body, hood and lock ring | s.s. 1.4418 |

| Frame top part and hood | s.s. 1.4401 UNS 31600 |

| Frame bottom part | Cast iron clad with stainless steel 1.4301 UNS 30400 |

| Gaskets and O-rings | Nitrile rubber |

Shipping data

| Separator incl. bowl and motor | 2,800 kg (6,200 lbs) |

| Bowl | 1,160 kg (2,600 lbs) |

| Gross weight | 3,200 kg (7,100 lbs) |

| Volume | 5.4 m3 (190 cuft) |

Technical specifications

| Throughput capacity | max. 85 m3/h (370 US gpm) |

| Bowl speed | 4,800 rpm |

| Bowl volume | 72 l (19 US gal) |

| Sludge space | 17 l (4.5 US gal) |

| Motor power installed | 45 kW (60 HP) |

| Inlet pressure at 60 m3 /h (260 US gpm) | 0 kPa |

| Sound pressure | 80 dB(A) |

| Overhead hoist lifting capacity | min. 1,200 kg (2,700 lbs) |

Dimensions