Alfa Laval P-separators 605/615

S and P Flex separation systems

Alfa Laval’s S and P Flex separation systems combine the high efficiency, low sludge output and low operating cost of Alfa Laval centrifugal separators with a flexible scope of supply. Extensive possibilities for the separation system layout and assembly make it possible to suit any engine room and any oil separation application.

In addition, S and P Flex separation systems feature the EPC 60 controller, which enables the intuitive navigation of menus, parameters and alarms. The EPC 60 controlle also has a modular construction for easy I/O board addition and replacement.

The S and P Flex separation concept includes the complete S- and P-separator range. These can be

combined in mixed ship sets, even within a single customer-specified module.

Application P-separators

P-separators are based on purifier technology, which means that the oil/water interphase is manually adjusted by means of a gravity disc. Because the separators do not automatically adjust to varying oil density, they are most suitable for economical cleaning of the following:

- Lubrication oils

- Distillates

- Lighter diesel oils

If the oil is well defined and does not vary in density, P-separators can also be manually adjusted to clean heavy fuel oils with densities up to 991 kg/m3 and viscosities up to 700 cSt/50ºC. P-separators are designed for automatic operation at sea and in automated power stations ashore.

Scope of supply

The S and P Flex separation concept provides a wide range of alternatives for P-separators. Depending on the need, a P-separator can be supplied as a separator and ancillaries, as a customer-specified module, or as part of a comprehensive package including services and orderspecific documentation.

Flex system

A P-separator with ancillaries in the form of optimized block components provides full say over the use of space. This allows for local modularization or do-it-yourself assembly.

Flex modules

A compact P-separator module can be built to a customer-specified configuration from a wide range of modular skids and machine blocks. Multi-modules are possible, as well as mixed modules including one

or more S-separators and/or P-separators for the simultaneous treatment of different types of mineral oils. All Flex modules are factory tested to ensure faster start-up and commissioning.

Features and benefits

- Small footprint, high flexibility

The small separator and the modular nature of the surrounding components allow easy installation and flexible positioning in the engine room. - Simple installation

No tank is needed to supply operating water and no pipe is needed to discharge it, which further simplifies installation. - Separate feed pump

A separate feed pump reduces pipework to and from the preheater. - High separation efficiency

An optimized design ensures the best possible separation efficiency from the bowl and disc stack. - Low oil loss

The separator’s highly efficient displacement ensures that virtually no oil is lost. - Efficient discharge

Separated sludge and water are efficiently removed from the system. - Easy operation and service

The PLC based EPC 60 controller is designed for “one-button” starts and stops, as well as intuitive menu navigation. Information about parameters and alarms can be easily accessed, which simplifies both operation and troubleshooting. The EPC 60 also has a modular construction that enables faster troubleshooting and I/O board replacement. - Remote monitoring

Using either Ethernet or Bus communication, Flex systems and modules based on P-separators 605/615 can be supervised remotely from the control room. A variety of alarm functions are available as standard, and extra I/O boards can be added to the EPC 60 controller in order to enhance its monitoring capabilities.

Operating principle

A Flex separation system based on a P-separator 605/615 is operated automatically by the EPC 60 controller, apart from the starting of the separator. Untreated oil, heated to the correct temperature, is fed continuously to the separator, which is driven by an electric motor via a friction clutch and belt.

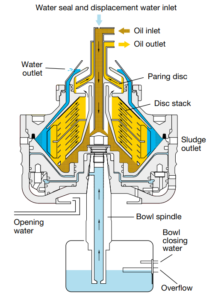

The separator bowl is fixed at the top of a spindle, which is supported by bearings and special composite springs. This bowl can be arranged as a purifier or as a clarifier. Both configurations remove sludge, which accumulates at the bowl periphery and is intermittently discharged.

In a purifier configuration, both sludge and water are separated from the oil, which means that water is continuously discharged from the bowl. The EPC 60 controller automatically controls the admission of water for the water seal and the displacement of oil prior to sludge discharge, but a gravity disc is needed to establish the correct interphase position in the separator bowl, i.e. the boundary between the oil and the water seal. The size of the gravity disc must be matched to the oil’s density, viscosity/temperature and feed rate to the separator.

In a clarifier configuration, a clarifier disc is fitted instead of a gravity disc. The water outlet is blocked, which means that the separator’s water-handling capacity is limited and that water accumulates like sludge.

During normal operation, vital process parameters are monitored. These parameters, as well as alarms, are indicated by easy-to-understand text messages on the LCD display of the EPC 60 controller.

The EPC 60 controller provides many alarm functions, including alarms for low oil pressure, high sludge tank level (if the optional sludge removal kit is included) and power failure. Additional functions are available for a vibration alarm when the optional vibration switch is fitted.