Home » Separators » Alfa Laval Separators »

Alfa Laval FESX 712B Separator

Alfa Laval separator centrifuges for the distillery and chemical industries are available in many different sizes and configurations, each one designed and adapted for dealing with the widely varying separation tasks required. The FESX 712B35CY is a medium-sized nozzle centrifuge optimised for large feed and solids flow rates and low power consumption. It is ATEX approved for zone 2.

Performance

The FESX 712B is ideal for separation of yeast after fermentation in distilleries. Other applications can be found in the starch industry, in the chemical and allied industries, and in other fermentation industries. In general, the FESX 712B will separate out solids with particle sizes down to 0.5 μm. In all cases, the solids must be heavier than the liquid.

Standard design

Separation takes place in the bowl, which is placed on a vertical spindle. An electric foot motor drives the spindle via a worm and a worm wheel. It is placed together with the centrifuge on a common foundation plate that is bolted to the floor. Two types of ATEX-approved explosion-proof motors are available: a standard motor for variable frequency drive or a control-torque motor. All metallic parts that come in contact with the process liquid are made of high-grade stainless steel. Via a power recovery ring, the separated liquid is leaving the centrifuge under gravity via a collecting cover. To recover energy from the discharged nozzle flow, the 12 nozzles are placed in the bowl periphery at a narrow angle from the tangent. The nozzles are made of erosion resistant material, suitable for abrasive solids. Liquid-wetted gaskets are made of nitrile rubber. The inlet is equipped with a screw coupling. The two outlets are equipped for hose connections.

Special features

A ring with vanes is fitted to the top of the bowl at the outlet of the separated liquid. The vanes re-direct the outflowing liquid so that part of the kinetic energy of the liquid is recovered, decreasing the power consumption of the machine.

Basic equipment

Centrifuge with motor, set of tools, speed sensor, vibration dampening feet, foundation plate and standard set of spares.

Options

- Standard electric motor suitable for variable frequency drive. A control torque motor is also available.

- A cover interlocking kit making it impossible to start the centrifuge unless the cover is properly mounted.

- Vibration monitor.

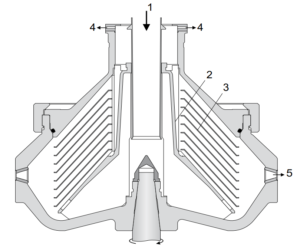

Operating principles

The feed containing the liquid and the solids is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe (1), and is accelerated in a distributor (2) before entering the disc stack (3). Separation takes place between the discs. The light phase moves through the disc stack towards the centre of the bowl, and is discharged via a power ring (4). In the case of a classification duty, the light phase contains the fine particles. The heavy solid particles are collected at the bowl periphery and continuously discharged through the nozzles (5).

ATEX design codes

| EX II 3 G T4 X for zone 2 | Electrically protected |

Utilities consumption

| Electric power | max. 55 kW |

| Safety water | 12–40 m3/h |

Material data

| Bowl body | s.s. 1.4462 UNS 31803 |

| Bowl hood, lock ring and distributor | s.s. 1.4462 UNS 31803 |

| Solids cover and frame hood | s.s. 1.4301 UNS S 30400 |

| In and outlet parts | s.s.1.4401 UNS 31600 |

| Frame bottom part | Cast iron |

| Gaskets and O-rings | Nitrile rubber |

Technical specifications

| Throughput capacity | max. 130 m3/h (570 US gpm) |

| Nozzle flow | max. 36 m3/h (160 US gpm) |

| Bowl speed | 4,800 rpm |

| Bowl volume | 31 l (8 US gal) |

| Motor power installed | 55 kW (75 HP) |

Shipping data

| Separator incl. bowl and 55 kW motor | 2,100 kg (4,600 lbs) |

| Bowl | 320 kg (700 lbs) |

| Gross weight | 2,700 kg (5,900 lbs) |

| Volume | 7 m3 (250 cuft) |

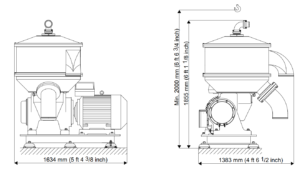

Dimensions