Home » Separators » Alfa Laval Separators »

Alfa Laval Culturefuge 100 Separator

Many new biological products are derived from fragile organisms. Although relatively easy to separate the trick is accomplishing the separation in a gentle manner without destroying the shear sensitive cell wall membranes that isolate the complex intracellular proteins from the extracellular liquid. If this can be avoided, downstream purification of the target proteins becomes much easier.

Applications

The machine is designed for clarification duty. Especially when clarifying liquids from shear sensitive particles. Applications that requires low oxygen pick-up can also take advantage of the hermetic features this machine offers.

Standard design

The machine consists of a frame that has a horizontal drive shaft, worm gear, lubricating oil bath and hollow vertical bowl spindle in the lower part. The bowl is mounted on top of the spindle, inside the space formed by the upper part of the frame, the ring solids cover, the collecting cover, and the frame hood. The liquid discharge system also rests on this structure. All parts in contact with the process liquid are made of stainless steel. The bowl is of the solids-ejecting disc type with an automatic hydraulic operating system for discharging. It is a so-called timer triggered partial discharge system, meaning that only part of the bowl content is emptied during pre-set discharge intervals. The discharge takes place at full speed without any interruption of the feed. The centrifuge is available with main connections as sanitary flanges and all other utility connections clamp type. The electric motor is of standard type and has a built-in variable frequency drive. The design conforms with a number of EC directives, and machine is made in accordance with the general directives for machinery. Finally, the centrifuge is equipped with nozzles for flushing of the bowl top, the bowl bottom and the cyclone.

Standard equipment

Each Culturefuge 100 centrifuge comes with control unit, electric motor, in- and outlet connections, spare parts kit and set of tools.

Material data

| Bowl body, hood and lock ring | s.s. 1.4462 UNS S31803 |

| Solids cover and frame hood | s.s. ASME SA-240 UNS 31603 |

| Cyclone | s.s. ASME SA-240 UNS 31603 |

| Bottom frame | Cast grey iron |

| In and outlet | s.s. mostly 1.4401 UNS 31600 |

| Gaskets and O-rings | EPDM rubber (FDA approved) |

Operating principles

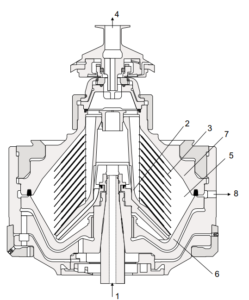

The feed is introduced to the rotating centrifuge bowl from the bottom through a hollow spindle (1), and is accelerated in a distributor (2) before entering the disc stack (3), where the separation takes place. The separated liquid phase leaves through the liquid outlet (4) at the top of the bowl. The collected solids in the solid space (5) are intermittently discharged from the periphery of the bowl. During normal production the operating water keeps the sliding bowl bottom (6) closed against the bowl hood (7). During discharge the sliding bowl bottom drops for a short time (less than a second) and the solids are ejected through the discharge ports (8). The high velocity of the ejected solids is reduced in the cyclone.

Available models

The Culturefuge 100 centrifuge is available in pressure vessel designs according to ASME or to PED. In addition, different surface finish executions are available:

| Bowl spindle | Ra 0.8 |

| Bowl spindle | Ra 0.5 and electropolished |

| Machine top part | Inside: Ra 0.8, Outlet cover: Ra 0.5 and electropolished |

| Machine top part | Inside: Ra 0.8, Outlet cover: Ra 0.8 |

| Machine top part | Inside: Ra 1.2, Outlet cover: Ra 1.2 |

| Separator bowl | Inside: Ra 0.5 and electropolished, Outside: Ra 0.8 |

| Separator bowl | Inside: Ra 0.8, Outside: Ra 0.8 |

| Separator bowl | Inside: Ra 1.2, Outside: Ra 1.2 |

Dimensions

Technical specification

| Hydraulic capacity | max. 2.0 m3/h |

| G-force | max. 12200 g |

| Bowl speed | max. 9650 rpm |

| Motor power installed | 7.5 kW |

| Sound pressure | 74 dB(A) |

| Overhead hoist lifting capacity | min. 100 kg |

Utilities consumption

| Electric power | 5.5 kW |

| Operating water | 0.3 l/discharge |

| Cyclone flush | 0 – 8 l/discharge |

| Cooling for seals | max. 300 l/h |

| Flushing above the bowl | 0 – 1 l/discharge |

| Flushing under the bowl | 0 – 1 l/discharge |

| Steam per sterilization cycle | 5 – 10 kg |

Shipping data

| Centrifuge with bowl with motor | 450 kg |

| Gross weight | 600 kg |

| Volume | 1.0 m3 |