Pentair Südmo Double Seal Valve SD Economic

Pentair Südmo Double Seal Valve SD Economic is an cost effective yet technologically-sophisticated alternative to liftable and balanced mixproof double seat valves.

Pentair Südmo Double Seal Valve SD Economic is an cost effective yet technologically-sophisticated alternative to liftable and balanced mixproof double seat valves.

The design of the SD Economic is based on many years of experience in valve construction and production. Pentair Südmo's SD Economic is an cost effective yet technologically-sophisticated alternative to liftable and balanced double-seat valves.

SD stands for single-disc Seat valve with Double seal functionality. With this type of valve, two incompatible media (e.g. CIP and product) can be separated in the pipelines without mixing. This is ensured by two separate seals, between which an open air space enables any potential leaks to be detected and removed. Additionally, the leakage chamber can be externally flushed by two valves fitted on each side.

Benefits

- Economic and compact alternative to liftable and balanced double-seat valves

- High protection against mixing through innovative positioning of seat seals

- Simple integration of flush/leakage valves into the equipment without welding

- Maintenance - easy, fast and safe

- Optional sterile barrier for critical products

Applications

Products

- Water - Beverages

- Beer – Spirits - Wine

- Food - Liquid Egg - Dairy Products

Applications

- Distribution of liquid products

- Distribution of CIP media

- Separation of product areas to CIP-supply and CIP-return

Meets the following market requirements

- Mix proof valve with low CAPEX and OPEX

- Safe separation of incompatible media in production

- Quick and safe cleaning in CIP process

- Minimized downtime and maintenance cycles

Valve position “Closed”

- Two incompatible media are separated without mixing (e.g. CIP and product)

- Flush/leakage valves open with spring force

- Any potential leaks are detected and removed

Valve position “Open”

- Upper and lower lines connected

- Flush/leakage valve closed with air pressure

- Recommended direction of flow during closing procedure (see arrows)

Flushing of the leakage chamber

- 180° offset positioning of flush valve prevents cleaning shadows

Sterilization

- Sterilization of seat area over flush valve

- Sterilization of stem area with optional sterile chamber

Innovative Sealing Solution: SAFE – DURABLE - EASY MAINTENANCE

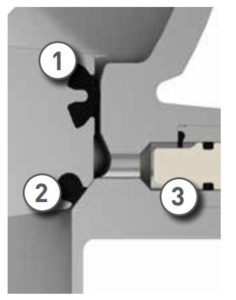

1. RSC (Radial Seal Complete) seal as radial sealing element

1. RSC (Radial Seal Complete) seal as radial sealing element

- Small contact area (optimized friction characteristics)

- Very good swelling compensation

2. O-ring as axial sealing element

- Metallic stop to protect against excessive stress

3. PEEK as sealing of leakage outlet

- Sealing close to product area

Technical Specification

Material

Product contact area

1.4404 (AISI 316L)

Non-product contact area

1.4301 (AISI 304)

Optional

High-quality materials

Seals*

EPDM / HNBR / FKM

*All seal qualities are FDA-compliant

Pressures

Control air pressure

Standard 6 bar (87 psi) – 8 bar (116 psi)

Operating pressure

Standard

DN 25-100/1.0’’-4.0’’ 6 bar (87 psi)

DN 125-150/5.0’’-6.0’’ 5 bar (72.5 psi)

Optional (for EPDM seals)

DN 25-100/1.0’’-4.0’’ 10 bar (145 psi)

Surfaces

Product contact: Ra ≤ 0.8 μm

Non-product contact: Ra ≤ 1.6 μm

Optional

High-quality surface finish, electro-polished

Connections

Pipe connections in accordance with

- DIN 11850-2 (DIN 11866-A)

- ASTM A270 (DIN 11866-C) (ASME BPE-2009)

Operating Temperatures

EPDM

EPDM

Standard

Hot water

+95 °C (203 °F) continuous

Steam

+130° C (266° F) continuous

+150 °C (300° F) brief sterilization (15-20 minutes)

Cold water

+1 to +2 °C (33.8 – 35.6°F) continuous

HNBR

HNBR

optional

Hot water

+95 °C (203 °F) continuous

Steam

+121° C (250° F) continuous

+140 °C (284° F) brief sterilization (15-20 minutes)

Cold water

+1 to +2 °C (33.8 – 35.6°F) continuous

FKM

FKM

optional

Hot water

+80 °C (176 °F) continuous

Steam

+121 °C (250° F) brief sterilization (15-20 minutes)

Cold water

+1 to 2 °C (33.8 – 35.6°F) continuous

Housing Variants

Feedback Systems

Position indicator ON/OFF

Position indicator ON/OFF

- Proximity sensor M12

- Hand guard prevents injuries

IntelliTop 2.0 control top

IntelliTop 2.0 control top

- Decentralized control unit

- Valve actuation system

- Position monitoring

- Valve/PLC interface