APV / SPX Double Seat Delta DKR2 Valves

Product Features and Benefits

Safe Separation of Incompatible Fluids

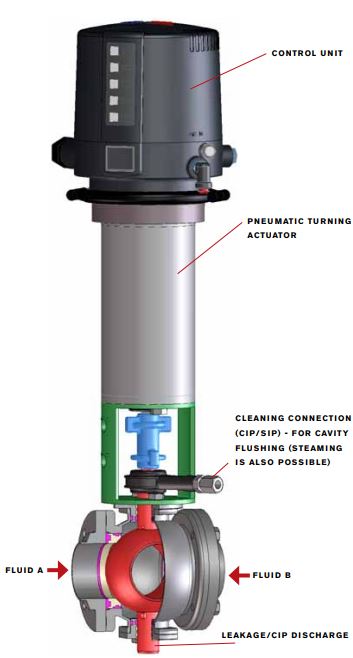

A design with two seat seals and a drainable separation cavity ensuring timely discovery of any leakage due to seal failure, makes the DELTA DKR valve ideal for applications where safeguarding against mixing of different media has the highest priority.

Highly Cleanable

The design is characterized by careful sealing with FDA compliant materials and the use of high-quality stainless steel. The CIP cleanability, including the leakage chamber between the housing globe and the ball, has been validated by an EHEDG test. Furthermore, steam sterilization of the leakage chamber is possible.

Water Hammer Safe

In process systems, water hammers can occur. Due to a design with two welded shafts, the DELTA DKR can withstand water hammers. The soft opening and closing characteristic of the valve prevent the DELTA DKR from causing water hammers as well.

No Pressure Drop

The DELTA DKR valves have spherical switching elements. When the valve is in the open position, a full bore will be achieved, i.e. no stem or disc to disturb the flow and virtually no pressure losses over the valve.

Suitable for Use in Pigging Systems

The full ported, straight-through design frees the flow from obstructions and makes the DELTA DKR valve the obvious choice for pigging systems. DELTA

DKR valves are used in process lines as well as in pig launching and receiving areas.

Space-Saving Design

The compact design minimizes space requirements thus enabling efficient process designs. Furthermore, no auxiliary valve is required to open or close the

leakage chamber.

Theory Of Operation

The field of application of the DELTA DKR valve comprises separation of two line sections with different fluids by two independent seals with an intermediate leakage chamber and a free drain to the atmosphere. During operation, leakages drain off from the leakage discharge.

The leakage chamber is cleaned by supply of cleaning liquids via the cleaning connection. The leakage chamber can be flushed with water or CIP liquids or sterilized with steam.

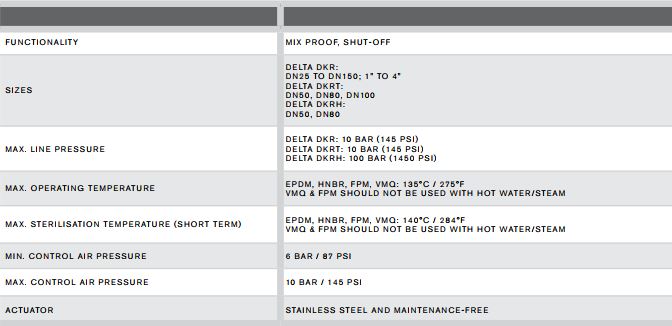

Product Specifications

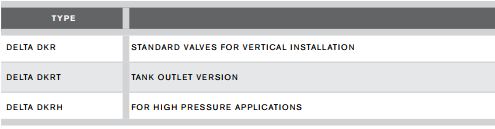

Delta DKR Designs Avaliable

Materials

Technical Data

Options and Accessories

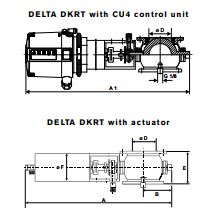

Delta DKRT

The DELTA DKRT is a special tank outlet version of the DKR valve. With a full ported and compact design the valves are particularly suitable for efficient

emptying of tanks with low outlet heights.

Delta DKRH

The DELTA DKRH is a high-pressure version of the DELTA DKR valve. The valve’s sturdy construction increases max. permissible line pressure in open or closed position to 100 bar (1450 PSI). Application examples are butter and

mayonnaise production.

Delta DKR For Horizontal Installation

DELTA DKR valves are also available for horizontal installation in horizontal as well as vertical pipelines.

Delta DKR with Leakage Reducer

It is possible to reduce leakage during the opening

and closing of the DELTA DKR valve by approximately

40% when installing a leakage reducer. The leakage

reducer is especially suitable for CIP applications and

can be retrofitted to installed valves as well.

Delta DKR with Leakage Collector

The leakage discharge on DELTA DKR valves can

be prepared for connection with a pipeline collecting

liquid discharged during operation. Weld end as well

as various pipe connections can be selected.

DELTA DKR with Thermal Jacket

A special version of the DELTA DKR valve is available for applications

involving temperature sensitive media, e.g. chocolate. The design facilitates

the heating of the valve ball.

Certification of Materials

DELTA DKR can be delivered with EN10204 – 3.1 as well as USP Class VI

certification.

DELTA CU Control Unit

DELTA DKR valves are available with proximity switch holder for external

proximity switches or a control unit.

The DELTA CU control units, used on various APV valve lines, are also

available with the DELTA DKR valves. The control unit operates as interface

between process control and valve and controls the electric signals and

pneumatics.

APV DELTA CU control units are very robust, easy to maintain, and

designed to operate in tough environments. Signal data are easily visible on

an exterior LED (electronic lights).

Interface Options

- CU4 Direct Connect (hard wire)

- CU4 AS-Interface, 31 or 62 slaves

- Profibus and DeviceNet (DELTA CU3)

Position Indication

- 2 internal feedback sensor switches for valve open/valve closed

position detection

Solenoid Valves

- 1 Solenoid

Protection Class

- IP67

- NEMA 6

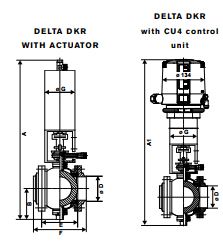

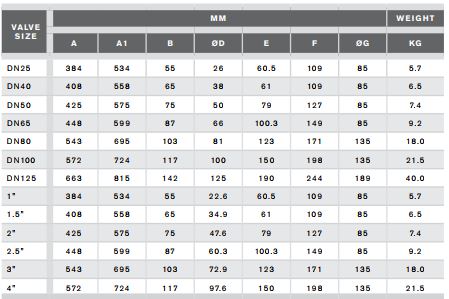

Dimensional Data

DELTA DKR

DELTA DKRT

DELTA DKRH