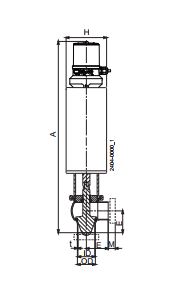

Alfa Laval Unique RV-ST Regulating Valve

Unique RV-ST is the third generation of Alfa Laval single seat regulating valves designed to meet the highest process demands of hygiene and safety. Built on a well-proven, platform from an installed base of more than one million valves, it is ideal for high volume, sanitary liquid processing applications where precision control of flow rate or pressure is required.

Working principle

The valve is remote-controlled by a digital electro-pneumatic process controller. It has few and simple moveable parts which results in a very reliable valve.

Technical Data

Max. product pressure: . . . . . 10 bar (1000 kPa).

Min. product pressure: . . . . . Full vacuum.

Temperature range: . . . . . . . . 10°C to +140°C (EPDM).

Air pressure: . . . . . . . . . . . . 5 – 7 bar (500 to 700 kPa).

Positioner data

Material: . . . . . . . . . . . . . . . PPS, stainless steel

Cover: . . . . . . . . . . . . . . . . PC

Seals: . . . . . . . . . . . . . . . . EPDM

Supply voltage: . . . . . . . . . . 24 VDC +/- 10%

Working temperature: . . . . . . 0 to 55 °C

Push-in fittings: . . . . . . . . . . ø6mm or 1/4”

Protection class: . . . . . . . . . IP65 and IP67

Position detection module: . . . Contact-free, wear-free

Communication: . . . . . . . . . . Analog

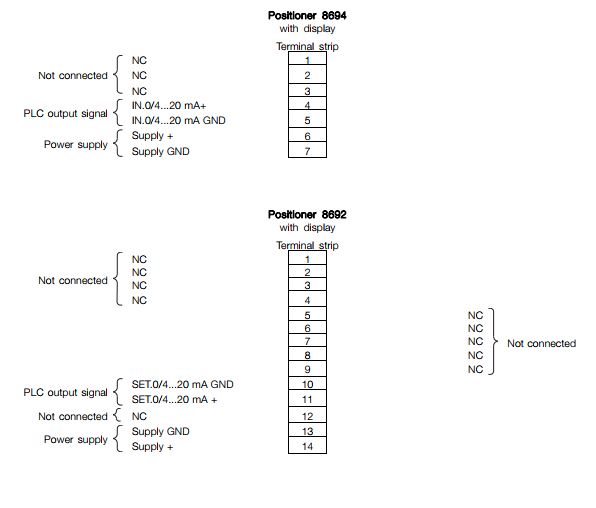

8692 Positioner – Top control with display

Setpoint setting: . . . . . . . . . 0/4 to 20mA and 0 to 5 5/10V

Output resistance: . . . . . . . . 0/4 to 20 mA: 180Ω

0 to 5/10V: 19Ω

Power consumption: . . . . . . < 5W

Cable gland: . . . . . . . . . . . . 2xM16x1,5 (cable-ø10mm)

Max. wire diameter . . . . . . . . 1.5 mm2

Physical Data

Product wetted steel parts: . . .1.4404 (316L)

External finish . . . . . . . . . . . .Semi-bright (blasted)

Internal finish . . . . . . . . . . . .Bright (polished), internal Ra < 0.8 µm

Other steel parts: . . . . . . . . .1.4301 (304)

Plug seal: . . . . . . . . . . . . . .EPDM

Other product wetted seals: . .EPDM (standard)

Other seals: . . . . . . . . . . . . .NBR

Valve Body Combinations

(IMAGE)

8694 Positioner – Basic control without display

Setpoint setting: . . . . . . . . .0/4 to 20mA

Output resistance: . . . . . . . .180Ω

Power consumption: . . . . . .< 3,5W

Cable gland: . . . . . . . . . . . .2xM16x1,5 (cable-ø10mm)

Max. wire diameter . . . . . . . .1.5 mm2

Standard design

Designed to deliver years of reliable performance, it features a broad selection of stainless steel, tapered valve stems along with the Unique actuator to ensure an outstanding degree of precise product control. Rugged and long-lasting plastic stem bushings eliminate metal-to-metal galling. The stems are threaded to the actuator shaft, eliminating the coupling between the stem and the actuator, thereby ensuring proper alignment. The plug seal is a standard seal used for the entire Unique Series. Bushings at the end of the actuator cylinder support the stem and ensure perfect alignment.

Other valves in the same basic design

- Sanitary Unique Single Seat

- Standard valve

- Reverse acting valve

- Long stroke valve

- Manually operated valve

- Aseptic valve

Options

a. Male parts or clamp liners in accordance with required standard

b. Product wetted seals in HNBR or FPM

c. Maintainable actuator

d. External surface finish blasted

e. Optional plug seal: HNBR or FPM

Note!

For further details, see instruction ESE02127

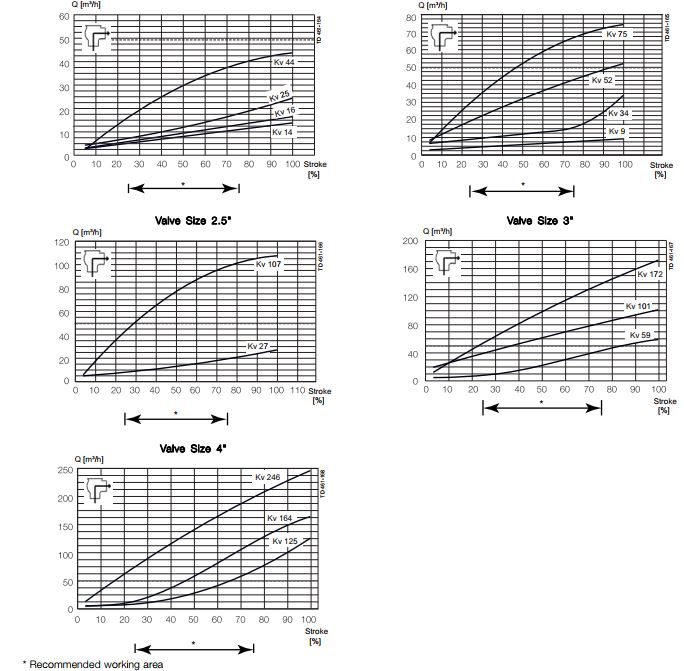

Pressure drop/capacity diagrams

Note!

For the diagrams the following applies:

Medium: Water (20° C)

Measurement: In accordance with VDI 2173

——– (dotted line) = Kv 49

Alfa Laval recommends max. flow velocity in tubing and valves to be 5 m/sec.

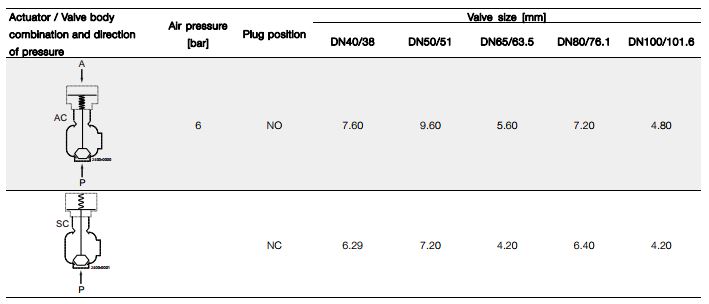

Pressure data

Table 1 – Shut-off valves

Max. pressure in bar without leakage at the valve seat

A = Air

P = Product pressure

AC = Air closes

SC = Spring closes

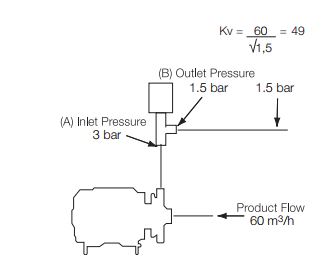

Valve Sizing

Flow Coefficients (Kv)

The following formula and flow coefficient values enable you to select the correct regulating valve for your application.

Formula for water and other products with a specific gravity equal to 1.0:

![]()

Formula for products with a specific gravity other than to 1.0:

![]()

Where:

Q =Product flow rate in m3 per hour

SG =Specific gravity of product

∆ P = Pressure drop across valve in bar

(inlet pressure minus outlet pressure)

Example of Kv Calculation:

Determine the proper size valve for 60 m3 per hour of water.

Inlet pressure of 3 bar

Outlet pressure of 1,5 bar

Solution: Inlet pressure (A) minus outlet pressure (B):

∆ P = 3 bar – 1,5 bar = 1,5 bar

How to Use Data to Select Valve Size

After the Kv factor for a specific application has been calculated,

locate the factor on the following page. Choose the curve closest

to the 50% stroke.

Using the above example, refer to the chart on the previous page you

will find that the Kv factor (49) is marked on the chart. You will find

that a 2″ valve crosses 1 Kv curve, 2½” 1 curve, 3″ 3 curves and 4″ 3

curves. The correct valve size to use is 2″ because Kv 49 crosses the

curve closest to the optimum operating point 50%. Alternatively the

4″ valve is also close to the 50%.

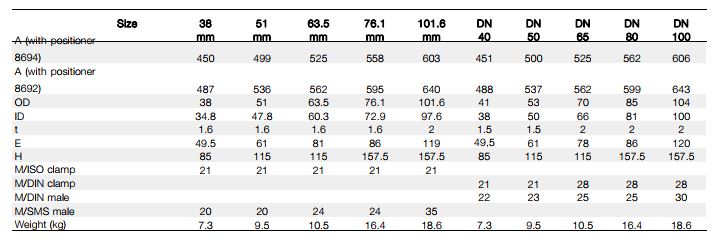

Dimensions (mm)

Air Connections Compressed air:

R 1/8″ (BSP) internal thread for actuator

Electrical connections