Alfa Laval S separators 921–987

S and P Flex separation systems

Alfa Laval’s S and P Flex separation systems combine the high efficiency, low sludge output and low operating cost of Alfa Laval centrifugal separators with a flexible scope of supply. Extensive possibilities for the separation system layout and assembly make it possible to suit any engine room and any oil separation application.

In addition, S and P Flex separation systems feature the EPC 60 controller, which enables the intuitive navigation of menus, parameters and alarms. The EPC 60 controller also has a modular construction for easy I/O board addition and replacement.

The S and P Flex separation concept includes the complete S- and P-separator range. These can be combined in mixed ship sets, even within a single customer-specified module.

Application S separators

S separators are based on Alcap technology, which means they automatically adjust the oil/water interphase based on the water content in the clean oil outlet. This makes them particularly suitable for separating heavy fuel oils with varying density, though they can be used to clean all of the following:

- Heavy fuel oils with densities up to 1 010 kg/m3 and viscosities up to 700 cSt/50°C (higher viscosities available upon request)

- Lubricating oils

- Distillates

- Lighter diesel oils

S separators are designed for automatic operation in periodically unmanned engine rooms at sea and in automated power stations ashore.

Scope of supply

The S and P Flex separation concept provides a wide range of alternatives for S separators. Depending on the need, a S separator can be supplied as a separator and ancillaries, as a customer-specified module, or as part of a comprehensive package including services and order-specific documentation. These S separators come equipped with energyefficient IE3 motors.

Flex system

A S separator with ancillaries in the form of optimized block components provides full say over the use of space. This allows for local modularization or do-it-yourself assembly.

Flex modules

A compact S separator module can be built to a customer-specified configuration from a wide range of modular skids and machine blocks. Multi-modules are possible, as well as mixed modules including one or more S separators and/or P-separators for the simultaneous treatment of different types of mineral oils. All Flex modules are factory tested to ensure faster start-up and commissioning.

Features and benefits

- Small footprint, high flexibility

The small separator and the modular nature of the surrounding components allow easy installation and flexible positioning in the engine room. - Alcap technology

A water transducer in the clean oil outlet automatically adjusts the oil/ water interphase to maximize separation performance. - High separation efficiency

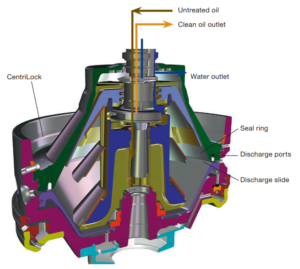

An optimized design ensures the best possible separation efficiency from the bowl and disc stack. - CentriShoot

The CentriShoot discharge system greatly reduces sludge volumes. Its fixed discharge slide flexes gently to expose the discharge ports, thereby eliminating metal-to-metal wear. - CentriLock

The CentriLock bowl-locking system uses a lightweight, non-threaded snap ring. This prevents wear by allowing easy removal without a sledgehammer. - Long service intervals

Wear-preventing features like CentriShoot and CentriLock reduce the consumption of spare parts and allow planned maintenance to be performed less often. This reduces operating costs. - Easy operation and service

The PLC based EPC 60 controller is designed for “one-button” starts and stops, as well as intuitive menu navigation. Information about parameters and alarms can be easily accessed, which simplifies both operation and troubleshooting. The EPC 60 also has a modular construction that enables faster troubleshooting and I/O board replacement. - Remote control and monitoring

Using Ethernet or Bus communication, Flex systems and modules based on S separators 921–987 can be operated and supervised remotely from the control room. A variety of alarm functions are available as standard, and extra I/O boards can be added to the EPC 60 controller in order to enhance its operating and monitoring capabilities.

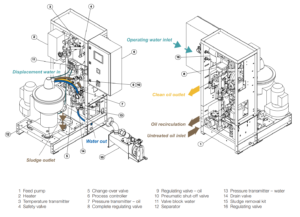

Schematic diagram

Operating principle

A Flex separation system based on an S separator 921–987 is operated automatically by the EPC 60 controller. Untreated oil, heated to the correct temperature, is fed continuously to the separator, which is driven by an electric motor via a friction clutch and belt.

The separator bowl is fixed at the top of a spindle, which is supported by bearings and special composite springs. During operation, separated sludge and water accumulate at the bowl periphery and are intermittently discharged by the high-precision CentriShoot discharge system.

The separator’s operation is based on the Alcap principle, which means the separator automatically adjusts to the nature of the oil. No gravity disc is needed. A water transducer in the clean oil outlet measures capacitative resistance and signals changes to the EPC 60 controller.

Depending on the water content, the EPC 60 either opens the drain valve or expels the water through the

bowl discharge ports during sludge discharge. A patented paring tube adapts itself to remove the water from the bowl while a paring disc pumps away the clean oil.

During normal operation, vital process parameters are monitored. These parameters, as well as alarms, are indicated by easy-to-understand text messages on the LCD display of the EPC 60 controller.

The EPC 60 controller provides many alarm functions, including alarms for low oil pressure, high sludge tank level (if the optional sludge removal kit is included) and power failure. Additional functions are available for a vibration alarm when the optional vibration sensor is fitted.