Alfa Laval Merco H-38

Upgrading to increase capacity up to 33 percent

Increased demand for ethanol and high fructose corn syrup has renewed interest in new processing strategies and equipment to improve efficiency and overall process economics.

To alleviate capacity constraints, Alfa Laval introduces the Capacity Booster Upgrade. This is a straightforward modification of your Merco separator at a lower capital cost than purchasing a new separator. Yet it brings you the benefits of both increased capacity and reduced energy consumption per unit.

• Increased capacity of up to 33 percent

• Energy savings of 25 percent or more

• Longer service life

• Easier to inspect and service

Increase capacity

Simply replace your Alfa Laval Merco H-36B rotor assembly and feed inlet assembly with a new Alfa Laval Merco H-38 rotor assembly and feed inlet assembly.

In addition to enhancing capacity, the Capacity Booster Upgrade includes new E-25 high efficiency nozzles with a special tool that makes the nozzles much easier to install and remove. The nozzles are made out of one piece of abrasion resistant material that results in extended nozzle life. The nozzles are also installed in bushings which minimize the risk of damage to the bowl wall.

Easier to save energy

Save energy whenever the additional capacity isn’t required. You have the flexibility to increase feed intake during peak production periods and reduce it as production slows. When operating at reduced production capacity, you can realize the same energy savings of 25 percent or more.

Easier to inspect and maintain

Does inspecting your disc stack take too much time? Then you’ll love two of the most useful features of the new rotor assembly. A new lock ring cuts the time required to remove the bowl cover for routine inspection. And a new design gives you fast access to the return tubes for inspection. Rather than spending time and energy to remove individual discs manually, simply lift the feedwell to remove the entire disc stack assembly at once.

Options

Machine sheave upgrade

Easier maintenance by a single person instead of two. No need for special tools.

Double underflow volute upgrade

For additional energy savings at higher nozzle flow.

Operating principles

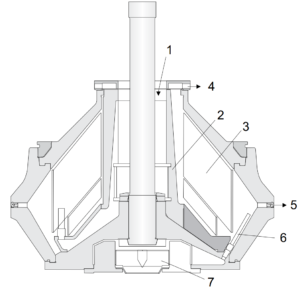

The feed, consisting of both liquid and solids, is led into the rotating centrifuge bowl from the top via a stationary inlet (1). It is then accelerated in a distributor (2), before entering the disc stack (3). The actual separation process takes place between the discs, with the liquid phase moving through the disc stack towards the center of the bowl. When it has reached the center, it is then discharged over a power ring (4). The solids, which are heavier, collect at the periphery of the bowl, and are then continuously discharged through the nozzles (5). Part of the concentrated solids discharged through these nozzles can be recirculated into the bowl periphery through the recirculation tubes (6), via the recirculation chamber (7). The wash water used to free solubles and other impurities from the solids can also be recirculated to the periphery of the bowl the same way. The bowl is mounted on a vertical spindle (8) that is driven via belts by a vertically mounted motor.

Utilities consumption

| Electric power | max. 260 kW |

| Safety water | max. 245 m3 /h (1,100 US gpm) |

| Wash water | max. 100 m3 /h (440 US gpm) |

Material data

| Rotor | s.s. 1.4462 UNS S 31803 |

| Rotor housing | Cast s.s. ASTM A-743 |

| Machine base, column and radial arm | Cast Iron |

| Gaskets and O-rings | Nitrile rubber |

Technical specifications

| Throughput capacity 1) 2) 3) | max. 300 m3 /h (1,330 US gpm) |

| Nozzle flow | max. 220 m3 /h (980 US gpm) |

| Bowl liquid volume | 202 l |

| Bowl speed | max. 2,950 rpm |

| Motor power installed | 225/260 kW (300/350 hp) |

| G-force | max. 4,850 g |

| Feed temperature range | 0–65°C |

Dimensions