Alfa Laval Merco CH-38 GOF

Alfa Laval separators for the starch industry are available in many different sizes and configurations, each one designed and adapted for dealing with the widely varying separation tasks required. The Merco CH-38 GOF is a dedicated starch centrifuge, designed for several applications in the maize wet milling process.

Applications

The CH-38 GOF is a nozzle centrifuge designed for continuous discharge of solids. It is used for classification of solids according to size, dewatering and washing of solids, and for clarification of liquids containing relatively high concentrations of solids.

The machine is Alfa Laval’s largest nozzle centrifuge for the maize starch industry. It is related to the widely used CH-36 but has a higher capacity and a larger bowl. It has a lower power consumption and is easier to assemble and disassemble.

The CH-38 GOF is used for processes that include primary separation, gluten thickening, millstream thickening and middling separation. Other common applications include washing and concentration of solids in the production of industrial minerals and chemicals.

Standard design

The centrifuge is equipped with sensors for monitoring bowl speed, vibration, temperature and oil pressure. Thirty peripheral nozzles are directed at a small angle to the tangent in order to recover energy from the material being discharged.

Special features

The CH-38 employs a special recirculation system that provides highly efficient separation. Solids can be recirculated to the nozzles at the same time as wash water is being recirculated. Working with the underflow draw-off valve, the return flow system provides a unique means of controlling the separation process. It allows the operator to control and optimise the separation process – by determining how much underflow is to be removed, how much is to be recycled back to the rotor and how much wash water is to be added. This makes it possible to use nozzles with a large diameter, which act as buffers to even out variations in feed concentration and to prevent blockages. The machine thus becomes more versatile, and can be easily adapted to changes in procedure.

The machine also features a built-in hydraulic hoist that eliminates the need for an external lifting device, and thus reduces the downtime required to service the centrifuge.

Basic equipment

The centrifuge is equipped with a motor, a self-cleaning strainer for the feed, speed and vibration sensors, oil temperature sensors for the spindle bearings and the motor winding, a hydraulic power unit for the lifting hoist, a set of special tools and a standard set of spares.

Options

Control-torque motors of four different power ratings are available. Frequency drive is also possible. The centrifuge bowl can be configured in classifier (PS) or clarifier (GT, MST, and CL) execution, with different disc spacings. A double underflow outlet is available for the MST version.

Operating principles

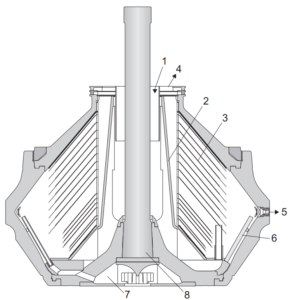

The feed, consisting of both liquid and solids, is led into the rotating centrifuge bowl from the top via a stationary inlet (1). It is then accelerated in a distributor (2), before entering the disc stack (3). The actual separation process takes place between the discs, with the liquid phase moving through the disc stack towards the centre of the bowl. When it has reached the centre, it is then discharged over a power ring (4). The solids, which are heavier, collect at the periphery of the bowl, and are then continuously discharged through the nozzles (5). Part of the concentrated solids discharged through these nozzles can be recirculated into the bowl periphery through the recirculation tubes (6), via the recirculation chamber (7). The wash water used to free solubles and other impurities from the solids can also be recirculated to the periphery of the bowl the same way. The bowl is mounted on a vertical spindle (8) that is driven via belts by a vertically mounted motor.

Utilities consumption

| Electric power | max. 260 kW |

| Safety water | max. 245 m3 /h (1,100 US gpm) |

| Wash water | max. 100 m3 /h (440 US gpm) |

Material data

| Rotor | s.s. 1.4462 UNS S 31803 |

| Rotor housing | Cast s.s. ASTM A-743 |

| Machine base, column and radial arm | Cast Iron |

| Gaskets and O-rings | Nitrile rubber |

Technical specifications

| Throughput capacity | max. 300 m3 /h (1,330 US gpm) |

| Nozzle flow | max. 220 m3 /h (980 US gpm) |

| Bowl liquid volume | 202 l |

| Bowl speed | max. 2,950 rpm |

| Motor power installed | 225/260 kW (300/350 hp) |

| G-force | max. 4,850 g |

| Feed temperature range | 0–65°C |

| Sound pressure | 85 dB(A) |

Shipping data

| Net weight | 9,700 kg (21,400 lbs) |

| Gross weight | 10,600 kg (21,400 lbs) |

| Volume | 18.5 m3 |

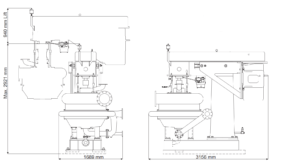

Dimensions