Alfa Laval MBUX 420

The Alfa Laval centrifuges for recovery of yeast and other microorganisms take advantage of the fact that the slurry of concentrated solids is pseudo-plastic and flows easily in the bowl against the centrifugal force. This means that the recovered solids can be obtained with a low demand on energy in a closed system under pressure. Therefore, the hygienic conditions are very good, further improved by a full-speed CIP procedure. The MBUX 420 has a bowl body in Super Duplex stainless steel, for added strength and corrosion resistance.

Applications

The solids discharging nozzle centrifuge type MBUX 420 is designed for separation of micro-organisms from fermentation broths, e.g. in chemical and pharmaceutical industries, and for yeast extract production.

Special features

With the patented Alfa Laval self regulating vortex nozzles the concentration of discharged solids phase can be kept at a high and even level irrespective of fluctuations in the feed flow or feed concentration. The centrifuge can thus be operated closer to the clogging point without increasing the risk of clogging. The light and heavy phase are both discharged under pressure which prevents foaming and simplifies installation by eliminating pump systems and improves the hygiene. Solids pockets in the bowl guide the solids to the concentrate tubes preventing accumulation of firmly packed solids and making separation and Cleaning In Place (CIP) easier and more effective. Automated CIP at full speed. Frame hood and solids receptacle are jacketed for circulation of cooling water, which also reduce the noise level. Frame hood is fitted with a spray nozzle for washing the outside ofthe bowl. A rotating liquid seal below the bowl seals off the bowl casing from the drive system.

Standard design

The MBUX 420 has all liquid-wetted parts in high-grade stainless steel and rubber sealings food approved EPDM or nitrile rubber. Connections for inlet, centrifugate and concentrate are hygienic screw couplings. The separator is equipped with speed and vibration sensors. The anchoring feet are equipped with vibration dampers. The MBUX 420 is driven via a belt by a flange-mounted controlled torque motor. The separator is delivered with the motor pre-mounted at the factory so there is no need for alignment on site.

Operating principles

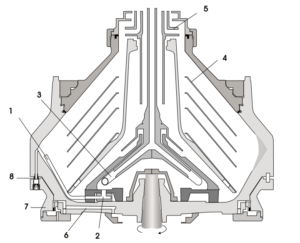

Separation takes place in the disc type bowl which is equipped with concentrate tubes and vortex nozzles. The heavy solids phase is moved outwards by the centrifugal force in to the solids pockets at the bowl periphery and from there through concentrate tubes (1) and internal vortex nozzles (2) into the paring tube chamber, where the concentrate is skimmed off by the paring tube (3) and discharged under pressure. The clarified liquid phase is displaced towards to the centre through the disc stack (4). This phase is then discharged under pressure by means of a built in paring disc (5). The bowl can be opened intermittently during production and/ or the cleaning cycle for ejections of solids while the machine continues to run at full speed. The hydraulic (6) controlled valve slide (7) under the bowl bottom opens the discharge valves (8) momentarily, permitting the ejections of solids.

Technical specifications

| Throughput capacity | max. 100 m3 /h |

| Solids handling capacity | max. 45 m3 /h |

| Feed temperature range | 0–100 ℃ |

| Feed inlet pressure required | max. 50 kPa |

| Centrifugate outlet pressure | max. 600 kPa |

| Bowl volume | 70 l |

| Concentrate outlet pressure, recommended | 300 kPa |

| Bowl speed, synchronous | 3,740 rpm |

| Motor power | 90/135 kW |

| Motor speed, synchronous 50/60 Hz | 1,500/1,800 rpm |

| Starting time | 7–11 mins |

| Stopping time with brake | 25–30 mins |

| Sound pressure | 92 dB(A) |

| Over head hoist lifting capacity | 3,500 kg |

Material data

| Bowl body | s.s 1.4501 UNS S32760 |

| Bowl hood and lock ring | s.s 1.4462 UNS S31803 |

| Frame lower part | grey cast iron |

| Frame upper part and hood | s.s 1.4401 UNS 31600 |

| Gaskets and O-rings | Nitrile rubber or food grade EPDM |

Utilities consumption

| Electric power, max | 100 kW |

| Operating and sealing water | 150–300 dm3 /h |

| Safety water | 2–50 m3 /h |

| Flushing liquid, at 100 kPa | 600 l/h |

Shipping data

| Centrifuge with bowl and motor | 3,700 kg |

| Gross weight | 4,100 kg |

| Volume | 7.6 m3 |

Dimensions