Overview

This British, multinational automotive company manufactures leading technologies within its industry. Their adaptive approach to creating innovative technology includes putting engines through a rigorous testing process to ensure complete vehicle safety and performance.

Our client does this by running engines to the limit of their capacity on a testing rig. The heat produced by an engine is traditionally controlled by the vehicle radiator. However, as the engine test rig trials a range of engine designs, it wouldn’t be cost-effective or time appropriate to wait for a relevant vehicle cooling system to also be produced.

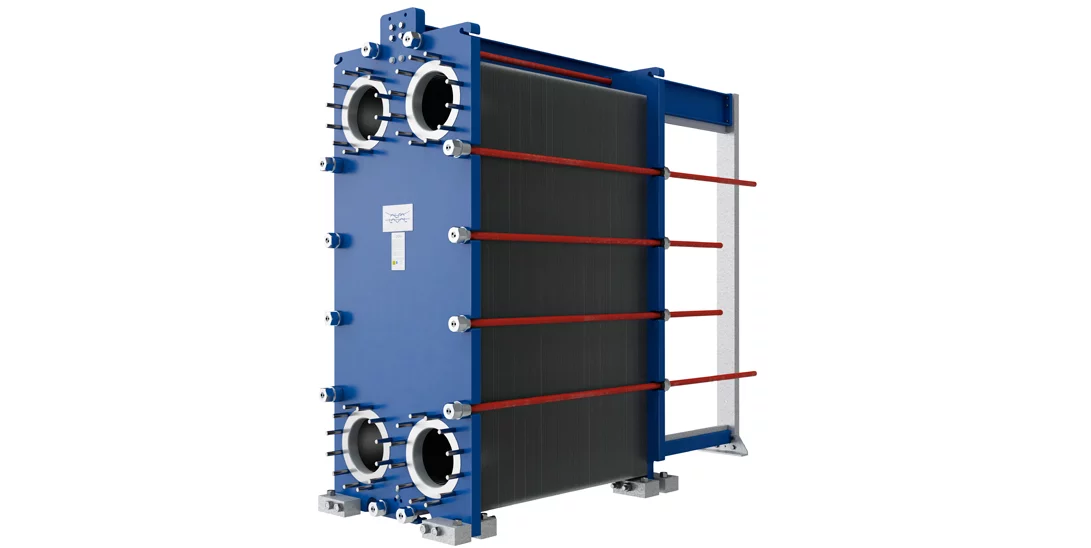

The engine testing rigs utilise highly efficient Alfa Laval gasketed plate and frame heat exchangers to simulate the vehicle radiator. A new testing rig was required to increase their engine testing capacity and Moody Heat Exchangers were able to provide expert knowledgeable support to ensure it met the customer’s requirements.

Our Approach

With a current, successful testing rig in place, the customer required a duplicate rig to increase testing capacity. After making inquiries with known suppliers they were unable to find the right solution. Searching online brought them across Moody Heat Exchangers.

Following a brief telephone call, a site visit was arranged. After a knowledgeable Sales Engineer attended site and built a true understanding of the customer’s requirements. With the assistance of Alfa Laval, Moody Heat Exchangers were able to design and offer the best heat exchanger solution for the customer’s application and recommended the supply of 27 Alfa Laval Gasketed Plate Heat Exchangers units.

As an Alfa Laval Authorised Distributor, the Moody Heat Exchangers’ team was able to arrange quick delivery from the Alfa Laval factory in Sweden.

Moody Heat Exchangers’ experienced team has a thorough knowledge of Alfa Laval’s heat transfer equipment. They were able to provide technical support and the best heat transfer solution throughout the process from inquiry to successful delivery to site.

Optimisation

For this automotive manufacturer, it was essential to be able to acquire the appropriate, fit for purpose units quickly. With the knowledge and experience developed over 45 years, Moody Heat Exchangers were able to meet this requirement.

Furthermore, they were also able to recommend replacement plates and gaskets for the existing testing rig to prolong the lifespan of the unit as a cost-effective alternative to replacing the complete units.

Results

Moody Heat Exchangers delivered the Alfa Laval gasketed heat exchangers to site within four weeks from the initial enquiry, ensuring the customers required delivery date was met and could be up and running with their new testing rig in a matter of weeks.

The Lead Engineer said “The automotive industry is highly competitive. Ensuring our testing facility was up and running quickly and professionally was of the utmost importance to us.

After speaking with the Moody Heat Exchangers’ team and detailing our requirements, it was clear that they would be able to ensure our needs were met. The process was simple and efficient and we look forward to working with Moody’s in the future”.

Summary

Alfa Laval gasketed heat exchangers were required in order to set up an additional testing rig within a large automotive manufacturer’s facility.

Moody Heat Exchangers were able to utilise their knowledge, experience, and excellent business relationship with Alfa Laval as a UK Authorised Distributor to meet the customer’s needs and ensure a quick turnaround of the required units.

Get in touch with us today to discuss your automotive PHE requirements – CONTACT US.