Alfa Laval IM 10 Rotary Jet Mixer

The patented IM 10 Rotary Jet Mixer (RJM) does not only mix fast, efficient and uniform but creates also the necessary process flexibility that makes it easy to switch to new product formulations with diverse viscosities, densities and volumes. Besides classic liquid to liquid mixing the RJM is excellent for gas and powder dispersion plus a superb tank cleaning machine.

Applications

Process and storage vessels between 1-10 m3 used in a wide range of industries such as: beer & beverage, food & ingredients, home & personal care, health care, biotech and chemical industry etc.

Operation

Secure that the mixer is positioned in the correct level and submerged into the liquid before round pumping or when adding any additional products from any up-stream pipe works.

Technical Data

Lubricant: . . . . . . . . . . . . . . . . . . . Self-lubricating with the mixing/cleaning fluid

Standard thread: . . . . . . . . . . . . . . 1” BSP or NPT, female, Top cone 1” BSP with hygienic seal

Min. tank opening: . . . . . . . . . . . . . See dimension drawings

Pressure

Working pressure: . . . . . . . . . . . . . 2-8 bar Recommended pressure

during mixing: . . . . . . . . . . . . . . . . 2-6 bar Recommended pressure

during CIP: . . . . . . . . . . . . . . . . . . 4-8 bar

Physical Data

Materials

Materials: . . . . . . . . . . . . . . . . . . . AISI 316L, AISI 316, SAF 2205 (UNS 31803), EPDM, PEEK, PVDF, PFA, Ceramics

Weight: . . . . . . . . . . . . . . . . . . . . 5.1 kg

Temperature

Max. working temperature: . . . . . . . . 95°C

Max. ambient temperature: . . . . . . . . 140°C

Certificates

2.1 material certificate.

Benefits

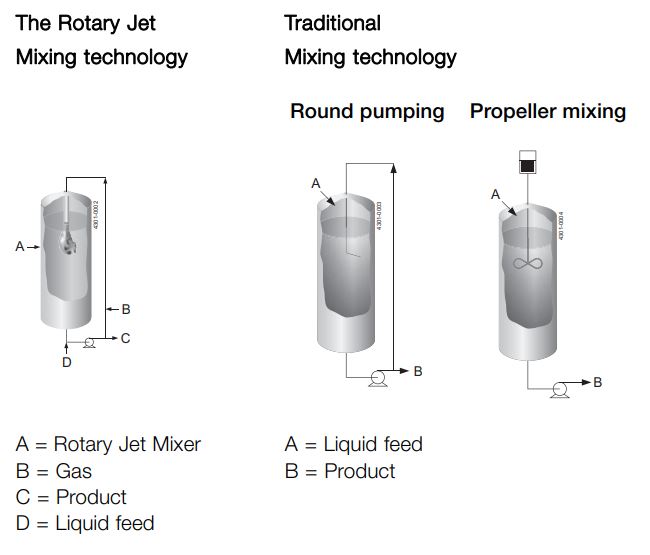

Using the IM 10 Rotary Jet Mixer makes it possible, at a modest investment, to perform fast and efficient mixing in a hygienic system. In traditional systems, using propeller mixers, a rotating shaft penetrates the tank wall, and a mechanical seal and a gear box are installed. With the Rotary Jet Mixer technology the shaft, seal and gearbox are eliminated, and a more hygienic design is obtained. With the Rotary Jet Mixing technology good mixing is achieved without the use of baffles. The Rotary Jet Mixer can also be used for gas dispersion. The IM 10 can furthermore be used for efficient CIP when the tank is empty, saving liquid, chemicals and energy compared to a fixed spray ball CIP system.

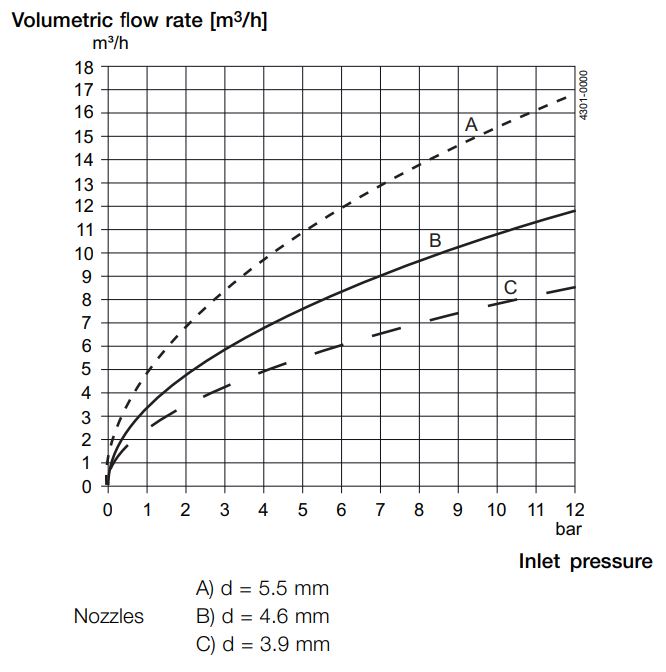

Flow Rate

Relationship between inlet pressure and flow rate for liquids with waterlike properties for the IM 10 Rotary Jet Mixer.

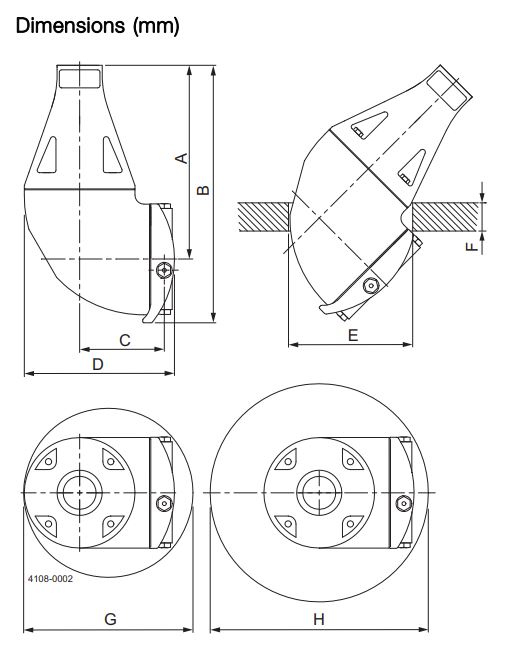

Dimensions (mm)

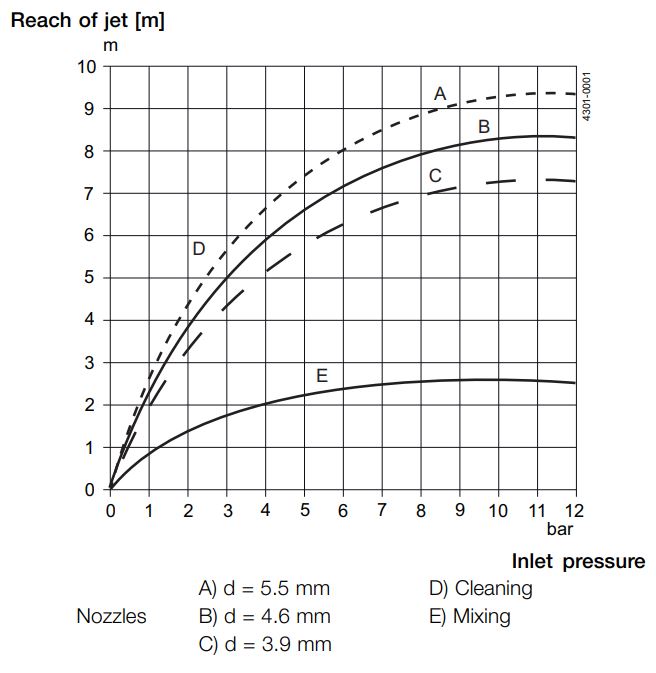

Reach of Jet

Reach of jet for the IM 10 during cleaning, and indicative reach of jet for mixing of liquids with water-like properties.

Mixing Technology

| A | B | C | D | E | F | G | H |

| 173 | 230 | 75 | 133 | ø110 | Max. 25 | ø150 | ø200 |

Keeping you processing

For more information about our products and services please get in touch!

JAMIE WETHERILL

Internal Sales Manager

Call: 01777 712101

Email: jamie.wetherill@moodydirect.com