Home » Separators » Alfa Laval Separators »

Alfa Laval Culturefuge 300 Separator

Many new biological products are derived from fragile organisms. Although relatively easy to separate the trick is accomplishing the separation in a gentle manner without destroying the shear sensitive cell wall membranes that isolate the complex intracellular proteins from the extracellular target proteins. If this can be avoided, downstream purification of the target proteins becomes much easier. The Culturefuge 300 is a steam-sterilizable hermetic machine designed for separation of mammalian and microbial cells as well as cell debris and suspended proteins at capacities up to 20 m3/h. The unique hermetic design with bottom feed gives not only a gentle acceleration of shear-sensitive particles; it also avoids pick-up of oxygen. The hermetic inlet together with the special geometry of the separator leads to maximum separation efficiency. Special attention has been paid to a hygienic, CIP-able design which is a pre-requisite for successful sterilization.

Applications

The machine is designed for clarification duty, separating particles from one liquid, especially shear sensitive particles. Applications that require low oxygen pick-up can also take advantage of the hermetic features offered by this machine. The sterilizability makes the machine suitable for most biotechnological separation duties.

Standard design

The machine consists of a frame that has a horizontal drive shaft, worm gear, lubricating oil bath and a hollow vertical bowl spindle in the lower part. The bowl is mounted on top of the spindle, inside the space (bowl casing) formed by the upper part of the frame, the solids collecting cover and the frame hood. The bowl casing is double-walled for cooling and noise reduction. The bowl is sealed off from this space by mechanical seals. There is also a mechanical seal at the bottom of the spindle, and a mechanical seal at the top of the spindle to make sterilization with steam possible. All metal parts in contact with the process liquid are made of stainless steel. The bowl is of the solids-ejecting disc type with an automated hydraulic operating system for discharging. It is a so-called timer triggered discharge system, meaning that the bowl content is emptied at pre-set discharge intervals. In production normally only part of the bowl content is emptied, whereas during CIP total discharges are possible. The partial discharge takes place at full speed without any interruption of the feed. The hydraulic/pneumatic system for discharge is mounted on the lower part of the frame. The centrifuge is available with main connections as sanitary clamps and all other utility connections of clamp type. The electric motor is suitable for variable frequency drive, which makes it possible to have bowl speeds down to 80 % of the maximum bowl speed. The design conforms to a number of EC directives, and the machine is made in accordance with the general directives for machinery. The machine is equipped with nozzles for flushing of the bowl top, the bowl bottom and the solids collecting chute.

Design features

- Designed for easy cleaning-in-place (CIP)

- Fully hermetic design for minimal shear stress and absence of oxygen.

- Design pressure of the bowl casing 300 kPa.

- Design pressure for the cooling jacket 300 kPa for connection to centralized cooling circuit.

- Bowl casing and cooling jacket designed according to ASME or PED.

- Sterilizable (SIP) with 210 kPa steam in a 30 min cycle, including discharge system.

- Most parts in contact with the process liquids available with two alternative surface finishes.

- Product wetted parts passivated (optional).

- All product wetted polymers and seal rings compliant with FDA regulation.

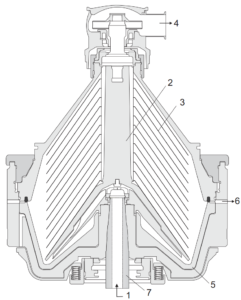

Operating principles

The feed is introduced to the rotating centrifuge bowl from the bottom via the hollow bowl spindle (1), and is accelerated in a distributor (2) before entering the disc stack (3). It is between the discs that the separation takes place. The liquid phase moves towards the centre of the bowl, from where it is pumped out under pressure by means of a built-in pump disc (4). The heavier solids phase is collected at the bowl periphery, from where it is discharged intermittently. The solids discharge is achieved by a hydraulic system below the separation space in the bowl, which at certain intervals forces the sliding bowl bottom (5) to drop down, thus opening the solids ports (6) at the bowl periphery. The bowl is mounted on a vertical spindle.

Utilities consumption

| Electric power | max. 20 kW |

| Flushing liquid, per discharge | 0-16 l |

| Operating liquid | 2.5 l per discharge |

| Steam at 210 kPa pressures | 20 kg per sterilization |

| Cooling liquid for frame parts | max. 550 l/h |

| Cooling liquid for oil cooler | max. 180 l/h |

| Cooling water for seats | min. 280 l/h |

Material data

| Bowl body, hood and lock ring | s.s. 1.4462 UNS S 31803 |

| Frame top part (ASME) | s.s. ASME S 31603 |

| Frame top part (PED) | Stainless steel 1.4404 (for pressurised equipment) |

| Frame bottom part | Cast iron, Clad with s.s. 1.4301 UNS S 30400 |

| Outlet parts | s.s. 1.4462 UNS S 31803 |

| Gaskets and O-rings product-wetted | EPDM rubber and PTFE acc. to FDA |

| Bowl seal ring | Amid polymer 66 acc. to FDA |

| Seal rings in and outlet | Resign impregn. Carbon Graphite acc. to FDA |

| Wear ring in and outlet | FDA approve self-sintered Silicon Carbide |

Connections

| Process (inlet and two outlets) | Clamp type, 63.5 mm |

| Utilities | Clamp type, various dimension |

Technical specification

| Throughput capacity | max. 20 m3/h |

| Solids handling capacity | max. 1200 l/h |

| Bowl volume | 30 l |

| Sludge space volume | 20 l |

| Discharge volume | 3-30 l |

| Bowl speed, separation | max. 5,119 rpm |

| Bowl speed, sterilization | max. 120 rpm |

| G-force | max. 7,425 |

| Motor speed synchronous 60 Hz | 1,800 rpm |

| Installed motor power | 22 kW (30 HP) |

| Starting time min/max | 8/10 mins |

| Stopping time with motor brake | 10 mins |

| Feed temperature range | 0 -100°C |

| Feed inlet pressure required at inlet flange | max. 200 kPa |

| Liquid outlet pressure at outlet flange | 200 kPa |

| Sound pressure | 73 dB (A) |

| Overhead hoist lifting capacity | min. 1,000 kg |

Shipping data

| Centrifuge incl. bowl and motor | 1,850 kg |

| Bowl | 600 kg |

| Gross weight | 2,150 kg |

| Volume | 5.0 m3 |

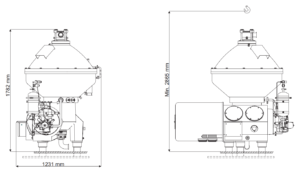

Dimensions