Home » Separators » Alfa Laval Separators »

Alfa Laval Clara 80 Separator

When producers of wine and other beverages consider using a separator for clarification purposes, flexibility and ease of operation are important issues. In production plants, the way such a separator is to be installed is also crucial. The unique design of the CLARA 80 mobile separation unit features a very small footprint, which reduces the amount of floor space needed. In order to speed up the start-up process and simplify subsequent operation, the CLARA 80 unit is delivered as a complete fully equipped system ready to install. CLARA 80 is highly efficient, and provides users with an environmentally friendly alternative to earth filters.

Applications

The CLARA 80 mobile separation unit is specially designed for use by the wine and beverage industries. CLARA 80 is well suited to clarifying the following products:

- white grape must (free run and press juice).

- young wine (still and sparkling).

- matured wine.

- fruit juices (deciduous, citrus and tropical).

- coffee and tea extract.

Special features of the separator bowl

The special geometry of the bowl ensures gentler acceleration for shear-sensitive agglomerates and particles. Combined with a new patented disc stack design, these significant improvements of the fluid dynamics lead to maximum separation efficiency, at the same time as reducing power consumption. The new paring disc design reduces oxygen pickup to a minimum, as well as preventing loss of volatile aromas or CO2. CLARA 80 is also available in a hermetically sealed version with a seal mechanism that makes it possible to clarify sparkling wines under pressure.

Standard design

The unit consists of a stainless steel skid fitted with a separator and all the auxiliary equipment needed for safe, efficient operation.

With the exception of the VNPX 507 separator, CLARA 80 includes:

- feed valve that is automatically closed when not in production mode.

- sight glasses at both inlet and outlet.

- sample valves at both inlet and outlet.

- flow meter with volumetric totalizer.

- pressure indicator at outlet.

- regulating valve for back pressure adjustments.

- water tank with integrated pump for constant operating water supply.

- solenoid valve block for addition of operating water, and solenoid valve for automatic flushing of bowl exterior.

- A Variable Frequency Drive (VFD) starts and drives the separator motor. The VFD also has a built-in control panel to monitor and control the different functions of CLARA 80. The control panel displays information about the operation, such as operating mode and time to next discharge. It also displays alarm messages. The operator’s interface is straightforward and easy to understand.

Options

A solids handling module can be fitted to the skid. This consists of a collecting tank and a pump. A stand-alone feed pump can also be supplied. The separator can also be set up with a mechanical seal at the liquid outlet. This makes it possible to clarify sparkling wine without loss of CO2. The separator can be fitted with cover switch and vibration sensor.

Operating principles

The feed containing the liquid and the solids is led into the unit through connection 201 and then into the separator. The solids are collected in the periphery of the rotating bowl and are discharged at preset intervals. The solid part is discharged from the separator through a cyclone and leaves the module from connection 222, alternatively through an integrated solids pump. The clarified liquid is pumped out of the rotor by means of a built-in paring disc and then passes a flow meter, a pressure indicator, a sight glass and a regulating valve. The clarified liquid leaves the module through connection 220.

Technical specification

| Throughput capacity | 9000 l/h (76 US barrels/h) |

| Solids discharge volume | 2.1 litres (0.55 gal) |

| Feed temperature range | 0–100 °C (32–212 ℉) |

| Bowl speed | 8,400 rpm |

| Feed pressure required | 0–200 KPa (29 psi) |

| Outlet pressure available | 0–700 kPa (102 psi) |

| Sound pressure | 81 dB(A) |

| Separator motor | 11 kW |

| Feed pump motor | 2.2 kW |

| Solids pump motor | 0.86 kW |

| Recommended fuse | at 400V 25 amp |

Connections

| Product inlet, outlet | NW32 acc to DIN11851 |

| Water | Hose nipple 19 mm |

| Solids cyclone | Hose 101 mm |

| Solids pump | NW25 acc to DIN11851 |

Utilities consumption

| Power consumption (separator) | 10.1 kW at 8 m3 /h |

| Water consumption | up to 48 l/h (0.2 USgpm) |

| Required water pressure | 0 bar |

Material data

| Bowl body | s.s. 1.4501 UNS S32760 |

| Bowl hood, lock ring and distributor | s.s. 1.4462 UNS S31803 |

| Solids cover and frame hood | s.s. 1.4401 UNS 31600 |

| In and outlet parts | s.s. 1.4401 UNS 31600 |

| Frame bottom part | Cast grey iron |

| Piping | s.s. 1.4407 UNS S30400 |

| Gaskets and O-rings | Nitrile rubber |

Shipping data

| Complete module incl. bowl & motor (net) | 830 kg (1,830 lbs) |

| Gross weight | 1025 kg (2,260 lbs) |

| Volume | 3.8 m3 (134 ft3 ) |

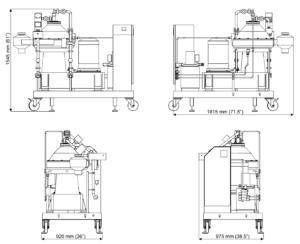

Dimensions