Home » Separators » Alfa Laval Separators »

Alfa Laval Clara 601S Separator

The Alfa Laval centrifuges for the beverage industries are available in many different sizes and configurations, each one designed and adapted to the widely varying separation tasks encountered. With a feed flow capacity of up to 55 m3/h (240 US gpm) and very high solids handling capability Clara 601S meets conditions common in the beverage industries. The Clara 601S is a clarifier that provides intermittent discharge of solids in a very dry state thanks to the SmartEject system. The unique hermetic inlet through a hollow spindle not only gives an extremely gentle acceleration of shear-sensitive agglomerates, it also reduces power consumption.

A computerized system ensures control and repeatability of the discharge volume. The machine features a combination of a high g-force, a high standard of hygiene and automated operation. The Clara 601S is also equipped with Oxy-Stop, which is a hydrohermetic seal for minimal oxygen pick-up of the clarified liquid.

Applications

The Clara 601S is specially designed for various process steps in the production of wine, fruit juice, tea and coffee. It is used for removing suspended solids with a particle size of 0.5–500 µm. The solids content in the feed is normally in the range of 0.1–10 % by volume, but may also be higher.

Standard design

The machine consists of a frame that has a horizontal drive shaft, worm gear, lubricating oil bath and vertical bowl spindle in the lower part. The motor is of a type suitable for variable frequency drive. The bowl is mounted on top of the spindle, inside the space formed by the upper part of the frame, the solids collecting chute, and the frame hood. The feed and the liquid discharge system also rest on this structure. All metallic parts that come in contact with theprocess liquid are made of high-grade stainless steel. Liquidwetted rubber gaskets are made of FDA approved nitrile rubber. The frame upper part and the hood are cooled with water, which reduces temperature increase of the process medium to a minimum and at the same acts as a sound dampener. The centrifuge is equipped with sensors for monitoring bowl speed and vibration level. Flushing takes place inside, above and under the bowl, in the solids collecting ring, and in the Oxy-Stop seal.

Special features

The Clara 601S is based on a unique, semi-hermetic design concept. The hermetic, bottom-fed inlet ensures a gentle acceleration of the process liquid up to full bowl speed. This minimizes splitting of shear-sensitive particles, maximizing separation performance. An added advantage is reduced power consumption.

The discharge volume is adjustable. Together with the triggering system it ensures discharge of solids with high dry matter content, thus minimising product losses, a clean bowl and reliable operation. The separator has a hydro-hermetic Oxy-stop seal, which minimises oxygen pick-up and is equipped with a built-in paring disc for the separated product, eliminating the need for an external pump.

The bowl casing is jacketed for cooling and sound dampening. The cooling of the solids collecting chute ensures against burning-on of solids. The sliding bowl bottom is fitted with an easily exchangeable erosion liner for protection against possible abrasive solids. The presence of a frequency inverter in the VFD system gives a number of advantages, including low starting current, and a short-time power supply at external power failure.

Basic equipment

The Clara 601S is normally delivered as a complete system to simplify installation and start-up. The system includes valve modules for process and service liquids, frequency inverter and control system. The centrifuge includes motor, set of tools, speed sensor, vibration switch, vibration-dampening feet, and standard set of spares.

Options

The disc stacks are available with two different diameters, giving different solids space volumes, and with two different disc spacings. The frame can be delivered in two executions: painted or clad with stainless steel. In the latter case, the motor has a stainless steel cover.

Optional extras

The Clara 601S is available with a cover-interlocking kit to make it impossible to start the centrifuge unless it is properly assembled, and additional service kits.

Operating principles

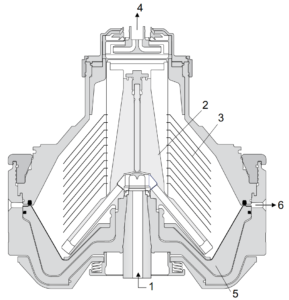

The feed is introduced into the rotating centrifuge bowl from the bottom via the hollow bowl spindle (1) and accelerated in a distributor (2) before entering the disc stack (3). The separation takes place between the discs. The liquid phase moves towards the centre of the bowl where it is pumped out under pressure by means of a built-in paring disc (4). The heavier solids phase is collected at the periphery of the bowl where it is discharged intermittently via the centrifuge cyclone. The solids are discharged by a hydraulic system below the separation space in the bowl, which at certain intervals forces the sliding bowl bottom (5) to drop down thus opening the solids ports (6) at the periphery of the bowl. The triggering system functions by outlet turbidity and/or timer.

Material data

| Bowl body, hood and lock ring | s.s. 1.4418 |

| Solids cover and frame hood | s.s. 1.4401 UNS 31600 |

| Bottom frame | Cast iron, with or without cladding with stainless steel 1.4301 UNS 30400 |

| Inlet and outlet | stainless steel 1.4401 UNS 31600 |

| Gaskets and O-rings | Nitrile rubber |

Shipping data

| Separator incl. bowl and motor | 2,550 kg (5,600 lbs) |

| Bowl | 1,150 kg (2,500 lbs) |

| Gross weight | 2,800 kg (6,200 lbs) |

| Volume | 10 m3 (350 cuft) |

Technical specifications

| Throughput capacity | max. 55 m3/h (240 US gpm) |

| Bowl speed | 4,800 rpm |

| Bowl volume | 59 l (15.6 US gal) |

| Sludge space volume | max. 32 l (8.4 US gal) |

| Motor power installed | 52 kW (70 HP) |

| Inlet pressure | at centrifuge inlet flange 140 kPa (20 psig) |

| Sound pressure | 78 dB(A) |

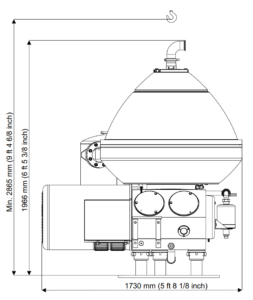

| Overhead hoist lifting capacity | min. 1,200 kg (2,700 lbs) |

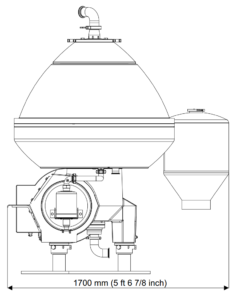

Dimensions