Home » Separators » Alfa Laval Separators »

Alfa Laval Clara 250 Separator

The Alfa Laval Clara 250 is a complete “plug & play” separation system, based on the PX 810 centrifuge, which is mounted on a flexible and cost efficient module. It is designed for the food and beverage industries but can also be used for general purpose duties.

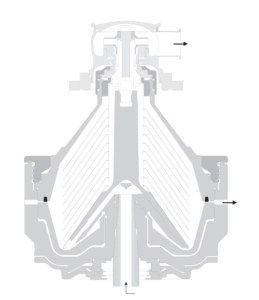

The Alfa Laval PX 810 separator, which is the core component of the Clara 200 system, is a bottom fed separator with Alfa Laval’s unique fully hermetic design, which provides very gentle product treatment and zero oxidation as well as minimized energy consumption. The bowl is of steep angle design with all product wetted parts in stainless steel and o-rings and gaskets are food grade. It has variable discharge volume and is suitable for clarification duties with a wide range of solids content.

Standard design

The Clara 250 system includes:

- Valves and components for product and utility handling.

- Inductive flow meter with volumetric totalizer.

- Sight glass in product outlet.

- Regulating valve for back pressure control.

- Pressure sensor with alarm for operating water supply.

- Flushing of the bowl exterior surface.

- Electrical cabinet, including PLC type EPC 60.

- Possibility to communicate with external system by Modbus TCP.

Technical specification

| Hydraulic capacity (max) | 25 m3 /h |

| Solids space clarifier | 5 lit |

| Discharge volume | 3-10 lit |

| Power consumption max | 16 kW |

| Motor power | 18.5 kW |

| Weight complete module incl. separator | 2200 kg |

| Weight separator, total | 1370 kg |

| Weight bowl | 310 kg |

| Weight motor | 170 kg |

Operating principles

The process liquid is continuously fed into the unit through the connection 201 and then into the centrifuge bowl through the hollow drive spindle. The solids are collected in the periphery of the rotating bowl and are discharged at preset intervals. The solids are discharged from the separator via a cyclone and leaves the module from connection 222, alternatively via an integrated solids pump. The clarified liquid is pumped out of the bowl by means of an built-in impellar and the clarified liquid leaves the module through connection 220.