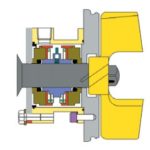

APV / SPX C Series Centrifugal Pump

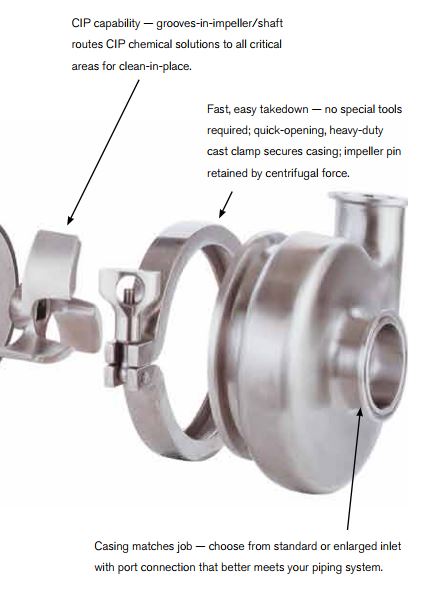

C Series Centrifugal Pumps find broad application throughout sanitary and industrial processes. These rugged pumps accommodate a wide range of solids and liquids under a variety of flow conditions and deliver long service with minimum downtime.

Features and Benefits

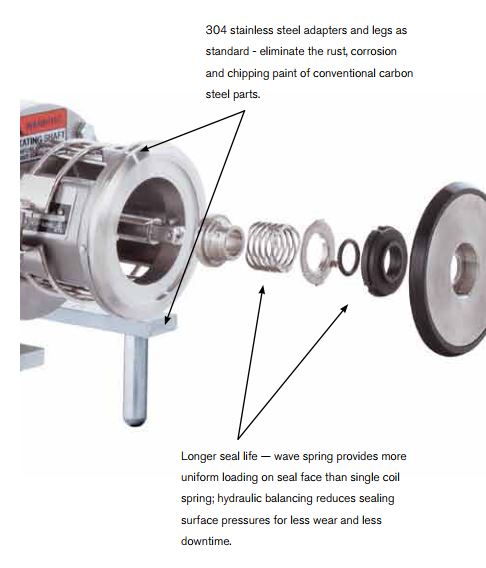

- Hydraulic balancing reduces pressure at sealing surface for less wear

- Easy-cleaning, open type impeller delivers smooth pumping performance

- Enlarged inlets available for larger suction lines

- Standard CIP capability

- 3A certified

Typical Product Applications

Beverage:

- Beer

- Cider

- Fruit Drinks

- Liquid Sugar and Glucose

- Soft drinks

- Wine

- Wort

Food:

- Animal oils

- Flavourings

- Pet food

- Soups & Sauces

- Vegetable juice

- Vegetable oils

- Vinegars

Dairy:

- Cream

- Milk

- Milk concentrate

- Raw milk

- Skimmed milk

- Whey

- Whey concentrate

Product Specifications

| Materials | |

| Casing | SS 316L |

| Impeller | |

| Impeller Pin | |

| Back Plate | |

| Shaft | |

| Adapter | SS 304 |

| Legs | |

| Motor Shroud | |

| Shaft Seal | Carbon/Stainless Steel (D Seal) |

| Optional Rotary Seal (DG Seal): Silicon Carbide, Tungsten Carbide | |

| Optional Stationary Seal (DG Seal): Silicon Carbide, Purebide, Ceramic and Tungsten Carbide | |

| Elastomers | Buna-n (FDA Complaint) |

| Optional: FKM, EPDM |

| Connections | |

| Standard | ISO2852, Clamp |

| Optional | Threaded Connections: ISO2853, SMS 1145, DS 722, DIN 11851, BS 4825, PART 5 (RJT) |

| Clamp: BS4825, Part 3 |

| Technical Data | |

| Max. Inlet Pressure | 1,75 Bar |

| Max. Operating Temperature | 100°C |

| Model | Inlet | Outlet | Maximum Impeller | Max Capacity (m3/h) | Max Head (m) | ||

| 2900 rpm | 3500 rpm | 2900 rpm | 3500 rpm | ||||

| C100 | 1½” | 1” | 3,68” (93mm) | 14 | 17 | 11 | 17 |

| C114 | 1½” | 1½” | 4” (102mm) | 29 | 34 | 15 | 23 |

| C114 | 2” | 1½” | 4” (102mm) | 30 | 40 | 15 | 21 |

| C216 | 2” | 1½” | 6” (152mm) | 50 | 63 | 36 | 52 |

| C216 | 2½” | 1½” | 6” (152mm) | 52 | 64 | 35 | 51 |

| C218 | 2” | 1½” | 8” (203mm) | 52 | 73 | 66 | 94 |

| C218 | 3” | 1½” | 8” (203mm) | 95 | 115 | 62 | 93 |

| C328 | 3” | 2” | 8” (203mm) | 122 | 155 | 68 | 93 |

| C328 | 4” | 2” | 8” (203mm) | 122 | 175 | 68 | 95 |

Shaft Seal Options

Type D – External Balanced Seat

This versatile, dependable seal finds broad use in sanitary and industrial applications. Seal material is carbon rotating on the stationary stainless steel.

Type DG – Clamped-in Seal Seat

This seal is ideal for applications where resistance to corrosion is required or for abrasive or non-lubricating products. The DG utilizes Type D rotating seal components; however, the stationary seal seat material is silicon carbide, and is reversible for extended seat life.

Type E – Double Mechanical Seal

This double mechanical seal can be pressurized with a flush media and discharged to drain. Ideal for vacuum, high temperature, abrasive or non-lubricating applications.

- Type D

- Type DG

- Type E