Alfa Laval MAB 206

Efficiant oil cleaning

Clean oil is crucial for the safe, reliable and economical running of virtually all kinds of equipment that uses oils for either fuel, lubrication or in hydraulic systems. Clean oil reduces wear and corrosion on all equipment installed downstream, thus helping avoid breakdowns and cutting back on downtime throughout a plant or installation.

The impact of contaminants in oil

Contaminants in lubricating and hydraulic oils have serious effects on system performance, operating costs and durability.

For example, the presence of solid particles:

- abrades metal surfaces

- increases friction

- clogs filters

Similarly, if water is present in the oil, this:

- causes corrosion

- reacts with additives

- forms oil/water emulsions

- causes significant deterioration in the performance of the oil.

- eliminates or reduces corrosion by removing any waterpresent in the oil

Standard equipment

The separator is working either with two or three phases and could easaly be changed between the two diffrent versions clarifier and purifier.

Features and benifits

Compact and robust design with the following benefits:

- Simple installation, operation and maintenance

- Internal paring disc for discharge of clean oil

- Large sludge space

- Sludge basket for easy removal of sludge

- Flexibility: the bowl may be used either as purifier or clarifier

- Extremely reliable, ensuring long service life eliminates or reduces corrosion by removing any waterpresent in the oil

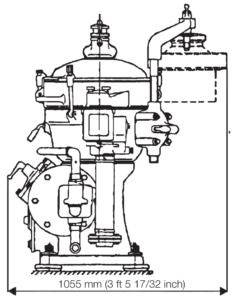

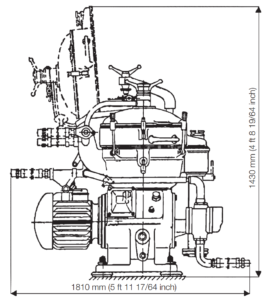

Dimensions

Technical specifications

| Max. throughput capacity | 10.6 m3 /h1 |

| Sludge and water space | 3.4 l |

| Feed temperature range | 0 – 100 °C |

| Installed motor power | 5.5 / 12 kW |

| Sound pressure | 75 dB(A) |

Utilities consumption

| Electric power | 3.3 – 8 kW |

Shipping data

| Net weight | 420 kg (926 lbs) |

| Gross weight | 525 kg (1 157 lbs) |

| Volume | 2.1 m3 |