Alfa Laval MBPX 810

The MBPX 810SGV-34CGL is a medium-sized unit in the range of centrifuges specially built for microbiological applications. The separation duties met with often require very high bowl speeds for an optimal performance in separation of solid particles with very small diameters.

Applications

The MBPX 810 separation system is based on the solids ejecting disc stack separator MBPX 810SGV-34CL in clarifier execution. It is equipped with variable discharge mechanism for timer triggered discharge of solids. It is used to remove suspended solids with particle sizes of approximately 0.5 to 500 µm from a liquid having lower specific gravity than the solids. The solids content is normally in the range of 0.1-10% by volume. The main applications are bacteria, rDNA products, enzymes, cell cultures and vaccines.

Design features

The MBPX 810 separator is equipped with the following features

- Variable partial discharge mechanism, allowing settable discharge volume

- Disc inlet for low shear acceleration of process media

- Variable speed to facilitate performance opimization

- A cooling system with a cooling jacket for the bowl enclosure including the solids collecting receptacle, and a cooling coil for the lubrication oil bath.

- Anchoring feet and vibration dampers

- All liquid wetted parts are in high grade stainless steel

- All liquid wetted elastomers are in FDA approved EPDM

- Hygienic design of solids handling area with internal spray nozzles

- Monitoring kit with sensors for bowl, speed, vibrations and operating water pressure, and, as option, a cover switch for preventing the motor from being started unless the separator top part has been properly mounted.

- Choice of large or small disc stack to accommodate low or high solids loading

- Choice of low flow or high flow paring disc

- Enhanced surface finish to less than 0.8 µm Ra for product contact parts, as an option.

Standard design

All liquid-wetted parts are made of high-grade stainless steel and liquid-wetted gaskets in FDA approved EPDM rubber. The machine is equipped with sensors monitoring vibration level and bowl speed. A cover switch prevents the start of the motor unless the machine top part has been properly mounted. The centrifuge is equipped with anchoring feet and MBPX 810 vibration dampers. The tools for assembly and disassembly of the bowl are made of stainless steel.

Options

Two different disc stacks for different solids space volumes are available. The centrifuge can be supplied as a complete system with the centrifuge mounted on a fixed base frame. On this frame is included process piping for liquids entering and leaving the centrifuge and for service media. Typically an optional pump removes the solids phase. The built-in electrical system includes starter for variable frequency drive, a PLC unit and a pneumatic unit.

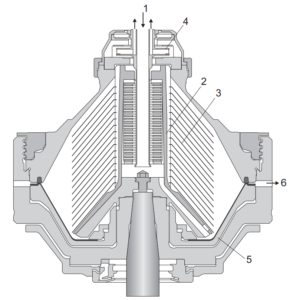

Operating principles

The feed is introduced into the rotating centrifuge bowl via a stationary inlet pipe (1) and is accelerated in the distributor (2) before entering the disc stack (3). It is between the discs that the separation takes place. The liquid phase moves towards the center of the bowl, from where it is pumped out under pressure by means of a built-in paring disc (4). The heavier solids phase is collected in the periphery of the bowl and is discharged at preset intervals through a cyclone. The solids discharge is achieved by a hydraulic system below the separation space in the bowl. When at pre-set intervals, the sliding bowl bottom (5) is forced to drop down, solids ports (6) are opened for the solids to be discharged.

Technical specifications

| Throughput capacity | max. 10 m3 /h (44 US gpm) |

| Solids handling capacity | max. 360/540 l/h |

| Feed temperature range | 0–100 °C (32–212 ℉) |

| Bowl speed | 7,488 rpm |

| Bowl volume | 15 l |

| Solids space volume | 6,8/9,4 l |

| Motor speed, synchronous 60 Hz | 1,800 rpm |

| Motor power installed | 22/25 kW (30/33 hp) |

| Starting time, min/max | 8–10 min |

| Stopping time without brake (average) | 45 min |

| Feed pressure required | 0–50 kPa (0–7 psi) |

| Outlet pressure available | 600–800 kPa (80–110 psi) |

| Sound pressure | 79 dB (A) |

| Overhead hoist capacity | 900 kg |

Material data

| Bowl body | EN 1.4418 |

| Bowl hood and lock ring | EN 1.4418 |

| Distributor | EN 1.4401 UNS 31600 |

| Solids cover and frame hood | EN 1.4401 UNS 31600 |

| In & outlet parts | EN 1.4401 UNS 31600 |

| Frame bottom part | Cast iron |

| Gaskets and O-rings | EPDM rubber acc. to FDA 21 CFR |

| Bowl tools | EN 1.4401 UNS 31600 |

Utilities consumption

| Power consumption | 17 kW @ 10 m3 /h (33 hp @ 110 US gpm) |

| Water consumption per discharge | 1 l/h (0.26 US gallon) |

| Required discharge water pressure | max. 50 kPa (7 psi) |

| Jacket cooling water consumption | 150 l/h |

Connections

| Product inlet, outlet | DN 50 acc. to DIN 11851 |

| Solids cyclone pipe | Clamp NW 63,5 acc. to ISO 2037 |

Shipping data

| Centrifuge incl. bowl and motor | 1,385 kg (3,060 lbs) |

| Bowl | 300 kg (665 lbs) |

| Gross weight | 2,000 kg (4,410 lbs) |

| Volume | 4–5 m3 |

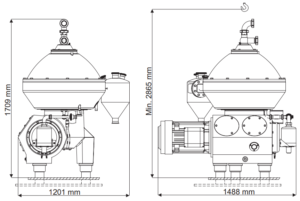

Dimensions