Alfa Laval MBPX 810H

The MBPX 810H is a medium capacity fully hermetic unit in the range of centrifuges specially built for microbiological applications. The separation duties met with often require very high bowl speeds for an optimal performance in separation of solid particles with very small diameters. The unique hermetic design with bottom feed gives not only a gentle acceleration of shear-sensitive particles, such as protein precipitates; it also prevents air entrainment that can cause problems in the downstream filtration process. The hermetic inlet leads to maximum separation efficiency by minimizing cell lysis. This also prevents release of unwanted intracellular proteins. The separation efficiency is further enhanced by a bowl geometry that uses the pseudo plastic nature of the solids phase. Flow control devices can be located downstream thus enabling implementation of an obstruction-free, full-bore feed arrangement. Special attention has been paid to a hygienic, CIP-able design.

Applications

The MBPX 810H fully hermetic separation system is used for removing suspended solids with particle sizes of approximately 0.5 to 500 µm from a liquid having a lower density than the solids. The solids content is usually in the range of 0.1-20% by volume.

The main applications are bacteria, rDNA products, enzymes, cell cultures and vaccines. It is also suitable for industrial fermentation processes where microbial cells are used for production of acids, chemicals, fuels, etc. Applications that require low oxygen pick-up can also take advantage of the hermetic features offered by the MBPX 810H separator.

Design features

The MBPX 810H separator is equipped with the following features

- Fully hermetic design for minimal shear stress, absence of oxygen, low power consumption and low noise level.

- Adjustable discharge volume ensuring discharge of solids with high dry matter content, thus minimising product losses or down-stream processing costs.

- High separation capacity due to the bowl geometry.

- Designed for easy cleaning-in-place (CIP).

- All product wetted polymers and seal rings compliant with FDA regulations or USP Class IV regulations.

- FDA compliant materials in the mechanical seals.

- Variable speed to facilitate performance optimization.

- A cooling system with a cooling jacket for the bowl enclosure including the solids collecting receptacle, and a cooling coil for the lubrication oil bath.

- Anchoring feet and vibration dampers.

- All liquid wetted parts are in high grade stainless steel.

- Monitoring kit with sensors for bowl, speed, vibrations and operating water pressure. As option, a cover switch for preventing the motor from being started unless the separator top part has been properly mounted.

- Choice of large or small disc stack to accommodate low or high solids loading.

- Enhanced surface finish to less than 0.8 µm Ra for product contact parts, as an option.

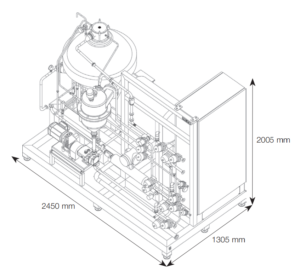

Complete system

The MBPX 810H separation system is flexible and designed to meet industry standards.

- The separator is mounted on a fixed base frame with process piping for service liquids and process liquids entering and leaving the separator.

- Clamp connections for improved hygiene.

- Control system with a PLC and HMI, suitable for connectivity (Profibus or Ethernet) with a supervising control system.

- Automatic CIP possibilities.

- Automatic flow control with magnetic flow meter and flow regulating valve.

- Back-pressure control.

- Optional – turbidity monitoring, replacement buffer liquid addition, solids receiving unit, mass flow meter (replacin magnetic flow meter) and temperature sensor on supernatant outlet provide enhanced installation flexibility to customer.

- Enhanced documentation supporting cGMP qualification is available and FAT is performed before shipping.

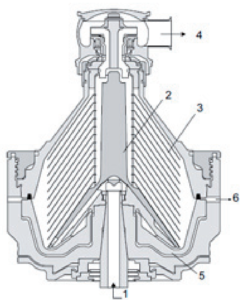

Operating principles

The feed is introduced to the rotating centrifuge bowl via a hollow spindle (1) and is accelerated in the distributor (2) before entering the disc stack (3). It is between the discs that the separation takes place. The liquid phase moves towards the centre of the bowl, from where it is pumped out under pressure by means of a built-in pump (4). The heavier solids phase is collected in the periphery of the bowl and is discharged at preset intervals through a cyclone. The solids discharge is achieved by a hydraulic system below the separator space of the bowl. When at present intervals, the sliding bowl bottom (5) is forced to drop down, solids ports (6) are opened for the solids to be discharged.

Technical specification

| Max throughput capacity | 15 m3/h |

| Max solids handling capacity | 300 or 540 l/h |

| Feed temperature range | 0 – 100 °C |

| Feed inlet pressure required, max. | 300 kPa |

| Liquid outlet pressure available upto | 520 kPa |

| Installed motor power | 18.5 – 25 kW |

| Sound pressure | 80 dB(A) |

Utilities consumption

| Electric power consumption, max. | 17 kW |

| Flushing & Operating water; max. momentary flow | 3 000 l/h |

| Consumption | Up to abt. 200 l/h |

| Cooling water, recommended flow | 120 – 150 l/h |

| Seal cooling water | 60 – 120 l/h |

Dimensions