Home » Separators » Alfa Laval Separators »

Alfa Laval FEQX 520S Separator

Alfa Laval separator centrifuges for the yeast and distillery industries are available in many different sizes and configurations, each one designed and adapted for dealing with the widely varying separation tasks required. The FEQX 520S31CG is the largest centrifuge with peripheral nozzles for these industries.

Applications

The FEQX 520S is specifically designed for separation of distiller’s, and fodder yeast as well as other fermentation broths. Separation of particles with sizes down to 0.5 µm is possible.

Typical processing capacity

Conventional fermentation of molasses/sugar w. recycle – 180 m3/h.

High conc. fermentation of molasses/sugar w. recycle – 120 m3/h

Spent sulphite liquor fermentation – 130 m3 /h

Fodder yeast at 5% DM in the feed – 90 m3/h

Standard design

Separation takes place in the bowl, which is placed on a vertical spindle. An electric motor mounted vertically drives the spindle near the bottom via a flat belt. Two motors are available: a standard motor for variable frequency drive or a control-torque motor. All metallic parts that come in contact with the process liquid are made of high-grade stainless steel. The 18 nozzles can be reached from the outside via a hatch in the frame hood, which enables technicians to replace them easily and rapidly without dismantling the frame. The nozzles are made of tungsten carbide, suitable for abrasive solids. The inlet and outlet device is equipped with flanges. The bowl casing has connections for flushing above and below the bowl.

Special features

The FEQX 520S is equipped with a solids recirculation system, which constitutes a unique means of controlling the separation process. Recirculation makes it possible to use a larger nozzle size and to meet fluctuations in the solids flow. Circulating oil ensures that the bearings are lubricated. An external pump maintains the necessary pressure.

Basic equipment

Centrifuge with motor, set of tools, speed and vibration sensors, oil pressure switch, temperature sensors for the main spindle bearing and the motor winding, vibration dampening feet, foundation plate and standard set of spares.

Options

Control-torque motors of four different power ratings are available. Frequency drive is also possible. The bowl is available in two versions, with or without erosion protection. Liquidwetted gaskets are made of nitrile rubber or food grade EPDM rubber. The centrifuge bowl is available with four different disc spacings. The connections are designed with either DIN or ANSI flanges.

Optional extras

The FEQX 520S can be fitted with a nozzle monitor. This consists of a microphone, which is hit by the jet from each individual nozzle. The signal is then transmitted to a box, which displays the result. The monitor shows whether the nozzles are clogged or worn out, thus enabling safe operation and high availability. A cover interlocking kit makes it impossible to start the centrifuge unless it is properly assembled. The FEQX 520S can be delivered as a complete system, including valve modules for process liquid and wash water, starter and control system. A conversion kit for rebuilding into FESX 520S is available.

Operating principles

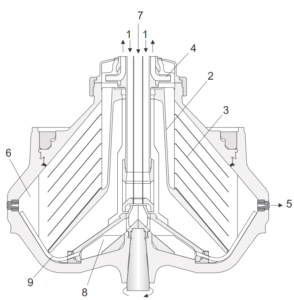

The feed containing the liquid and the solids is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe (1), and is accelerated in a distributor (2) before entering the disc stack (3). Separation takes place between the discs. The light phase moves through the disc stack towards the centre of the bowl, and is pumped out under pressure by means of a built-in paring disc (4). The yeast is collected at the bowl periphery and continuously discharged through the nozzles (5). Filler pieces (6) prevent build-up of the solids between the nozzles. The nozzle flow is collected in a cover around the bowl and further discharged into a pump. Part of the effluent from the pump can then be recirculated back to the nozzles through a pipe (7), a separate recirculation chamber (8), and recirculation tubes (9).

Utilities consumption

| Electric power | max. 170 kW |

| Safety water | 23-55 m3 /h |

| Flushing water | 60/460 l/h |

Shipping data

| Centrifuge incl. bowl and motor | 4570 kg |

| Bowl weight | 1050 kg |

| Gross weight | 4900 kg |

| Volume | 8 m3 |

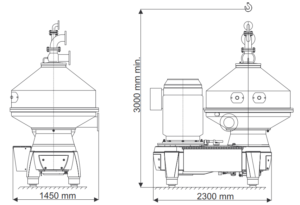

Dimensions

Technical specification

| Throughput capacity | max. 250 m3 /h |

| Light liquid flow | max. 200 m3 /h |

| Nozzle flow | max. 100 m3 /h |

| Bowl volume | 120 l |

| Bowl speed | 3750 rpm |

| Motor speed, synchr. 50/60 | 1500/1800 rpm |

| Motor power installed | 135/160/200 kW |

| Centrifugal force inside bowl | max. 6480 g |

| Starting time | 5-8 mins |

| Stopping time without brake | 80 mins |

| Feed temperature range | 0 – 100 °C |

| Feed inlet pressure at inlet flange | 100 kPa |

| Outlet pressure at outlet flange | max. 500 kPa |

| Sound pressure | 89 dB(A) |

Material data

| Bowl body | s.s. 1.4501 UNS S32760 |

| Bowl hood, lock ring and distributor | s.s. 1.4462 UNS S31803 |

| Solids cover and frame hood | s.s. 1.4401 UNS 316 00 |

| In and outlet parts | s.s. 1.4401 UNS 316 00 |

| Frame bottom part | Cast grey iron |

| Gaskets and O-rings | Nitrile rubber or food grade EPDM |