Home » Separators » Alfa Laval Separators »

Alfa Laval Brew 2001e Separator

Introduction

The use of separators in different brewery applications goes back to the beginning of the 1900’s. Based on the long-term cooperation with the brewery industry, Alfa Laval separators are specially designed for the requirements and demands of this industry.

Application

The Brew 2001e is designed and optimized for green-beer, beer pre-clarification and polishing, with the target to clarify beer with the best performance and yield.

Benefits

- High separation efficiency

- No oxygen pick-up

- Gentle treatment of the product

- Low power consumption

- Complete system handling both process and utility requirements

- Robust and reliable design

Design

The system consists of a separator, a valve module with valves and components for routing of product and utilities in and out from the separator. Control cabinet and starter cabinet are mounted on the valve module.

All metallic parts in contact with the process liquid are made of stainless steel. Gaskets and seals in contact with the product are made of FDA approved material and are approved according to food regulations (EC1935/2004).

The separation system is designed for completely automated Cleaning in Place (CIP).

Scope of supply

Disc stack separator with process liquid module including:

- Main process valves of butterfly type

- Flow regulating and counter pressure valves

- Flow meter of magnetic type

- Turbidity monitor for discharge triggering

- Main motor starter with VFD from ABB

- Control panel with Siemens PLC and HMI

- Sight glasses for in- and outlet

- Samples valves for in- and outlet

Options

- Feed pump

- Capacity control: Automatic regulation of the flow based on measurements of the feed solid content by inlet turbidity

- Solids control: Recirculation of the clarified product from the outlet of the separator to the inlet, in order to reduce outlet turbidity due to turbulent conditions in the bowl in discharge

- Solids receiving unit: Consists of a collection device and a pump, to pump away discharged solids

- Allen Bradley PLC and HMI

- Blending by-pass: The blending by-pass creates a shortcut between product feed and product outlet. The purpose is to mix unseparated product with separated product in order to achieve specific haze or yeast cell count in the product outlet.

Working principle

The product enters and leaves the separator via the valve module. The flow rate and the counter pressure in the outlet of the separator are controlled by the process liquid module. Discharge of solids from the separator bowl is triggered by a turbidity meter, placed in the outlet of the system. The discharged solids are pumped away by the optional solids receiving unit.

The valve module also controls the utility liquids for the separator’s discharge system and for flushing and CIP.

Technical data

Performance data

| Capacity | DN80: 550 hl/h (242 US gpm)

DN100: 850 hl/h (374 US gpm) |

| Max. motor power | 55 kW (73,7 HP) |

Connections

| Inlet | DN80: DIN 11851 Union

DN100: DIN 11851 Union |

| Outlet | DN80: DIN 11851 Union

DN100: DIN 11851 Union |

Material data

| Piping | DIN11850-2 (EN10357-A) AISI 304 |

| Customer connection | DIN11851 Union |

| Gaskets in system | EPDM product wetted parts |

| Pipe frame | AISI 304 |

| Cabinets | AISI 304 |

Weights (approximate)

| System weight incl. separator, bowl and motor | 5540 kg (12 220 lbs) |

| Bowl weight | 1150 kg (2550 lbs) |

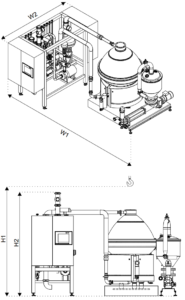

Dimensional drawing

Dimensions

| H1 | Min. 3380 mm (11 ft 1 1/16 inch) |

| H2 | 2485 mm (8 ft1 13/16 inch) |

| W1 | 3580 mm (11 ft 8 15/16 inch) |

| W2 | 3000 mm (9 ft 10 1/8 inch) |