Fristam FKL Series Pump

These circumferential piston pumps are extremely hygienic and offer high pumping efficiencies at discharge pressures up to 35 bar. Their revolutionary split-style gearbox makes maintenance quick and easy. FKLs are perfect for the dairy, meat, food, beverage, chemical, cosmetics and pharmaceuticals industries. Their smart design makes them extremely reliable and long-lasting.

Highest Quality

The FKL series complies with the highest standards and recommendations such as 3A. FKLs are built with superior materials. Corrosion-resistant steel such as chromium molybdenum steel 316L with a minimum thickness of 6.0mm, 3.1 material certification (certificate available upon request) and FDA certified elastomers guarantee maximum safety in the process. All pumps from the FKL series offer CIP and SIP.

Tight Internal Tolerances

They not only allow for higher pumping efficiency with incredible suction performance , but also reduce product damage due to shear. This results in very gentle product handling and ultimately better product handling and ultimately better product intergrity. The FKLs’ tight tolerances also make our pumps more resistant to wear from abrasive products – and enable them to handle goods with higher viscosities.

Optimal Design

The solid design and robust construction of Fristam FKL pumps ensure highest efficiency and operational reliability. Some of their most significant features are:

- high-pressure rotors

- offset rotor bolts

- the revolutionary split gearbox

- the extra-dimensional shaft

- seamless seal changeover

Split gearbox

This revolutionary design provides quick and easy access to bearings and shafts (available on models 13-250), ensuring long life and uninterrupted performance with:

- bearing-supported gears for even load distribution and less shaft deflection.

- large bearings for longer life and less maintenance.

- easy access with gearbox halves separable in less than one minute.

- complete shaft assembly with gears and bearings removable as one.

- simple reassembly after maintenance.

- labyrinth oil seals preventing water or product contamination, and protecting against high-pressure washing or product build up.

- low-maintenance lubrication

Extra-dimensional shaft

A Fristam FKL shaft is made from a single solid piece of 316L stainless steel. It has a larger diameter and a shorter overhung load to withstand elevated pressure without breaking.

Seamless seal changeover

FKL seals are completely contained within a cartridge. No extra modification is needed to switch from a single to a double seal or from O-ring to a mechanical seal.

Offset rotor bolts

The FKL’s special rotor bolts lessen the unwinding force of the product. They provide natural agitation in order to enhance cleanability in the cavity.

High-pressure rotors

Fristam FKL rotors are balanced, meaning the support hub is centred so that under high-pressure conditions the force acts through the central axis of the rotor in order to keep the lobes from from distorting. Our specific construction ensures that forces are distributed evenly and contact with the rotor case is prevented.

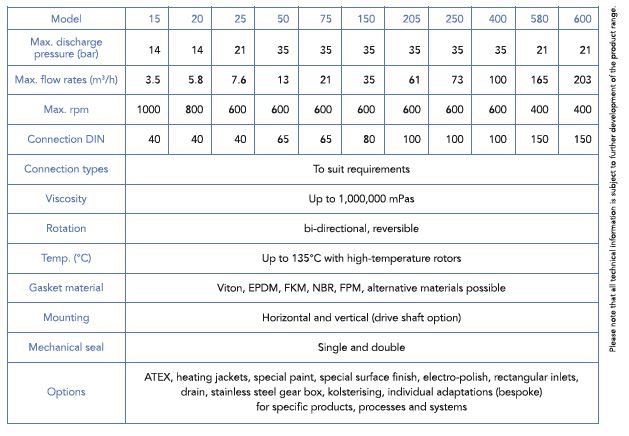

Fristam FKL Series Technical Specifications

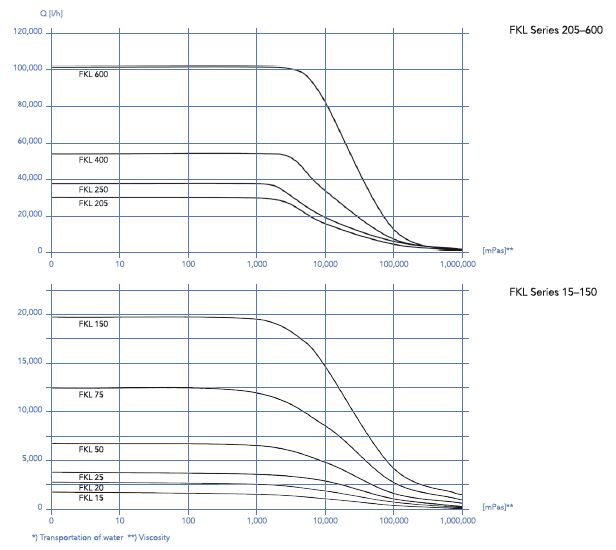

Characteristic Curves

Keeping you processing

For more information about our products and services please get in touch!

JAMIE WETHERILL

Internal Sales Manager

Call: 01777 712101

Email: jamie.wetherill@moodydirect.com