APV / SPX Double Seat Delta SWCIP4 Valves

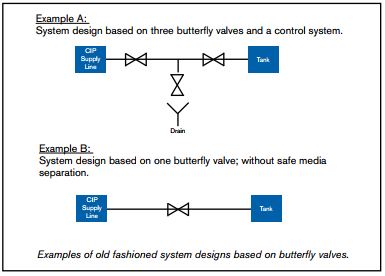

The DELTA SWcip4 valve is a modern double seal valve designed especially for CIP applications. The valve replaces old-fashioned block and bleed concepts based on three butterfly valves or double butterfly valves. With two serial seat seals and a separation cavity, the DELTA SWcip4 ensures that intermixing of CIP media is avoided. The valve is the answer to increasing product safety demands in CIP systems.

Simplified and Robust Design

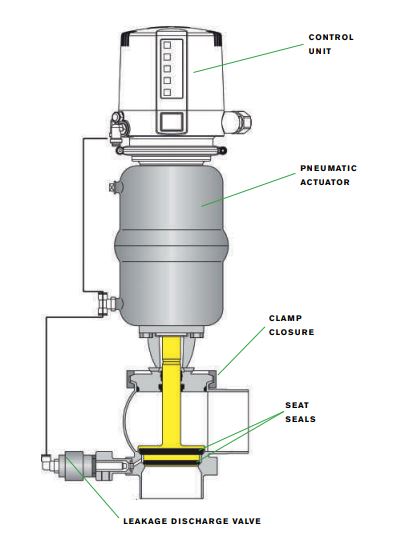

A simplified low-weight design with a sturdy globular valve body, two serial seat seals, only one leakage valve and a clamp housing closure, makes the DELTA SWcip4 valve a “fit for purpose” and price competitive solution.

Long Seal Life

Sealings designed with metallic stop ensure limited elastomer compression and, consequently, avoidance of sealing overstress.

Easy to Operate and Service

The simplified design with a leakage discharge valve controlled via air hose from the pneumatic actuator makes it very easy to install and operate the valve. Furthermore, the easy access to the hexagon nut shaft coupling positioned at the top of the actuator makes it simple to handle the valve during service.

Optimal Resistance Against CIP Media

The use of high-quality EPDM seals as well as high-quality stainless steel ensures optimal resistance against acids and caustic solutions. The profiled seat seals are marked with identification numbers preventing the installation of wrong seals.

Theory of Operation

The DELTA SWcip4 design is universally applicable and stands out for its high mechanical reliability and its absolute ease of handling. The SWcip4 valve is used for the safe separation of CIP liquids at crossover points of piping in CIP stations.

Separation is provided by two seat seals. A leakage chamber which is forcibly closed by a leakage valve or open to the atmosphere, is located between the seals. Leakage at the seat seals is indicated and discharged to the atmosphere by the leakage valve. The valves are operated by a maintenance-free actuator.

Production Specification

Materials

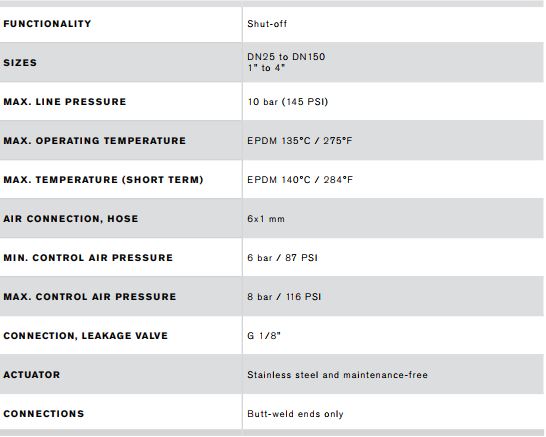

Technical data

Options and Accessories

DELTA SWcip4 valves are available with proximity switch holder or a control unit.

Proximity Switch Holder

Proximity switches to signal the final position of the valve seat can be mounted to the proximity switch holders if required.

Delta CU Control Top

The DELTA CU control units, used on various APV valve lines, are also available with the DELTA SWcip4 valves. The control unit operates as interface between process control and valve and controls the electric and pneumatic signals.

APV DELTA CU control units are very robust, easy to maintain, and designed to operate in tough environments. Signal data are easily visible on an exterior LED (electronic lights).

DELTA CU control units are available with or without a NOT element. A NOT element provides automatic air assist to back side of piston to increase product holding pressure.

Interface Options

- DELTA CU4 Direct Connect (hard wire)

- DELTA CU4 AS-Interface, 31 or 62 slaves

- Profibus and DeviceNet (DELTA CU3)

Position Indication

- 2 internal feedback sensor switches for valve open/valve closed position detection

Solenoid Valves

- 1 Solenoid

Protection Class

- IP67

- NEMA 6

Dimensional Data

Additional Technical Information

Maximum Holding Pressures (Without Not Element)

Kvs Values