APV / SPX V2 Series Centrifugal Pump

APV Fluid Handling offers an economical solution to an increasing range of pumping applications: the V² Series — a simplified maintenance friendly and efficient centrifugal pump featuring a four-blade, fully open, non-clog impeller that is the optimum design for sanitary service.

Features and Benefits

- Meets all standards: Sanitary models are manufactured from FDA approved materials, meet the requirements of the 3-A Sanitary Standards, carry the BISSC seal of approval and are approved by the USDA Meat and Poultry Division.

- Choice of seal types: the V² pumps are available with three different seal types to accommodate various applications and ensure optimum seal performance for the product being pumped. The standard product seal for all models is Type 1, a positive drive, single mechanical design.

- Hydraulically balanced and externally mounted. It suits general purpose applications such as milk products, beverages, fruit juices, organic acids, alcohols, process water and vegetable oils.

- Engineered for in-place cleaning: All V² Series Centrifugal Pumps are engineered for modern cleaning and sanitising techniques. The square impeller drive has grooves that allow circulation of cleaning and sanitising solutions along the shaft and behind the impeller. The separate impeller and shaft design enhances cleaning and inspection. Pump disassembly is quick and easy for complete manual cleaning and inspection. Parts and assemblies are not difficult to align. No special tools are required.

Materials

The casing has controlled wall thickness and dimensional accuracy throughout. The back plate is machined from stainless steel plate. A unique clamping assembly uses clamp rings with a self-locking internal angle that resists distortion and provides optimum sealing between the casing and back plate. The clamp rings are investment cast for greater strength than stamped clamp rings common to many sanitary pumps. A replaceable seat is provided in the back plate with optional seal types 2 and 5. This is reversible, providing a new wear surface without part replacement.

Typical Product Applications

Food and Beverage:

- Fruit Juices

- Water

- Beer

- Organic Acids

- Alcohols

- Beverage Syrups

- Tallow

Dairy:

- Milk

- Cream

- Ice Cream Mix

Emulsions:

- Sauces

- Ketchup

- Vinegar

- Brine

- Edible Oils

- Yeast Slurry

Options and Accessories

Connections

- Butt weld, plus five sanitary ferrule options

- 150 lb ANSI flange and male pipe thread for non-sanitary applications

Seal Options

- Type 2 APV product seal/ replaceable seat

- Replaceable seat provides a harder, wear-resistant stationary seat for extended life

- Cascade Water Flush

- For Type 1 and Type 2

- Recommended for products containing fines or particulates: brine’s; low vacuums; where caramelisation may occur (liquid sugars, HFCS, honey, syrups, molasses); and where flush water can discharge onto floor

- Type 5 contained water flush double seals (APV & John Crane)/ replaceable seat

- Double inside/outside APV hydraulically balanced inside; John Crane 8B2 hydraulically balanced outside

Other Pump Options

- Non-polished stainless steel surface (industrial applications)

- Case drain connections

- Stainless steel and painted carbon steel assemblies

- Stainless steel leg kit

Specifications

Data summary listed are inlet, outlet and impeller sizes, along with the Best Efficiency Point and shut-off head for each model. Capacity (Q) shown in U.S. gpm. Impeller diameter shown is maximum.

| Pump Models | Unit | Pump Casing | Maximum Impeller Size | Performance at B.E.P | |||

| Inlet x Outlet | 1750 RPM | 3500RPM | |||||

| – Q –

GPM M3/HR |

– Head –

FT Meters |

– Q –

GPM M3/HR |

– Head –

FT Meters |

||||

| 4V2 | in | 1.5 X 1.5 | 3.8 | 37 | 13 | 74 | 45 |

| mm | 38 X 38 | 97 | 8.4 | 5 | 16.8 | 13.7 | |

| 4V2 | in | 2 X 1.5 | 3.8 | 42 | 13 | 84 | 52 |

| mm | 51 X 38 | 97 | 9.5 | 4 | 19.1 | 15.8 | |

| 6V2 | in | 2 X 1.5 | 5.8 | 85 | 33 | 158 | 143 |

| mm | 51 X 38 | 148 | 19.3 | 10 | 35.9 | 43.6 | |

| 6V2 | in | 2.5 X 1.5 | 5.8 | 80 | 36 | 160 | 144 |

| mm | 63 X 38 | 148 | 18.2 | 11 | 36.3 | 43.9 | |

| 8V2 | in | 2 X 1.5 | 7.8 | 117 | 37 | 234 | 266 |

| mm | 51 X 38 | 200 | 26.6 | 20.4 | 53.2 | 81.7 | |

| 8V2 | in | 3 X 2 | 7.8 | 137 | 63 | 274 | 252 |

| mm | 76 X 51 | 200 | 31.1 | 19.2 | 62.2 | 76.8 | |

| 8VS2 | in | 3 X 2 | 7.8 | 231 | 63 | 462 | 252 |

| mm | 76 X 51 | 200 | 52.5 | 19.2 | 104.9 | 76.8 | |

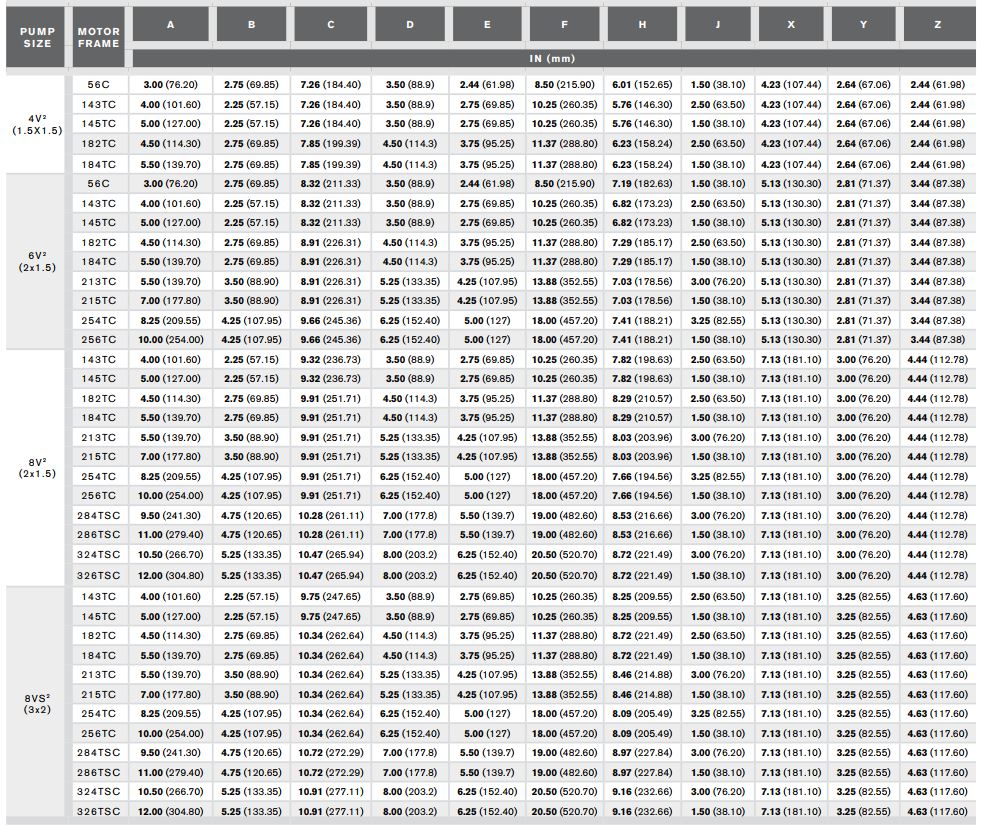

Dimensions

These dimensions are based on smallest size inlet and outlet with S-Line connections and standard TEFC motor. Refer to factory supplied drawings for detailed dimensions showing other connection sizes and types.

Note: Dimensions are approximate.

Note: Dimensions are approximate.