Alfa Laval LKH Multistage Pumps

LKH-110, LKH-110/P and LKH-120/P

Application

LKH-110, -110/P and -120/P are highly efficient multistage centrifugal pumps, which meet the requirements of hygienic applications. The LKH-110, the LKH-110/P as the LKH-120/P are available with 2, 3 and 4 stages.

Standard design

Alfa Laval multistage pumps are designed to be cleaned in place. The pumps have a stainless steel shroud for protection of the motor, and the complete unit is supported on four adjustable stainless steel legs.

Shaft Seals

The multistage pumps are equipped with either an internal single or a flushed shaft seal. Both have stationary seal rings made from silicon carbide and rotating seal rings in carbon or silicon carbide. –

– SiC/C material combination, outlet pressure up to 20 bar

– SiC/SiC material combination, outlet pressure up to 40 bar

Technical Data

Materials

Materials

Product wetted steel parts: . . . W. 1.4404 (316L) and Duplex steel

Other steel parts: . . . . . . . . . Stainless steel.

Product wetted seals: . . . . . . EPDM.

Other O-rings: . . . . . . . . . . . EPDM.

Finish: . . . . . . . . . . . . . . . . Standard blasted.

Connections for FSS:

6mm tube/Rp 1/8″

Motor

Foot-flanged motor according to the IEC metric standard, 2 poles = 3000/3600 rpm. at 50/60 Hz, IP 55 (with drain hole with labyrinth plug), insulation class F. Standard motors with a fixed ball bearing on drive side are fitted to LKH-110 pumps whereas special motors with special bearings are fitted to LKH-110/P and LKH-120/P pumps. Min/max motor speed: All variants . . . 900 – 3600 rpm

Warranty

Extended 3-years warrenty on LKH pumps. The warrenty covers all non wear parts on the condition that genuie Alfa Laval Spare Parts are used.

Operating Data

Technical data

Max. outlet pressure, LKH-110/P, LKH-120/P:

– Limited by the strength of the pump casing: 4000 kPa (40 bar) temperature < 40°C.

– Limited by the strength of the pump casing: 2000 kPa (20 bar) temperature > 40°C.

Temperature range: . . . . . . . . -10°C to +140°C (EPDM).

Water pressure: . . . . . . . . . .Normally atmospheric, max. 1 bar

(flushed seal).

Water consumption: . . . . . . .0.25 -0.5 l/min. (flushed seal)

Noise level (at 1 m): . . . . . . . .60-80 dB (A).

Max. inlet pressure

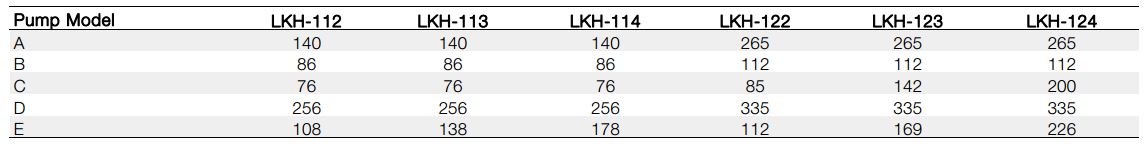

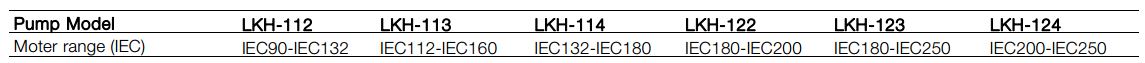

Pump specific measures

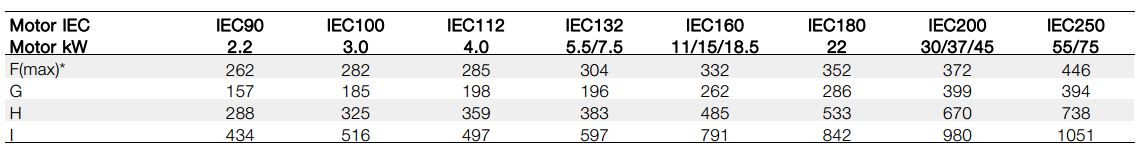

Motor specific measures

*Possible to reduce dimension F by min. 59 mm for all pump models. For smaller models it will be possible to reduce dimension F even further.

Motor overview

Dimensional data are based on 2 pole, ABB motors.

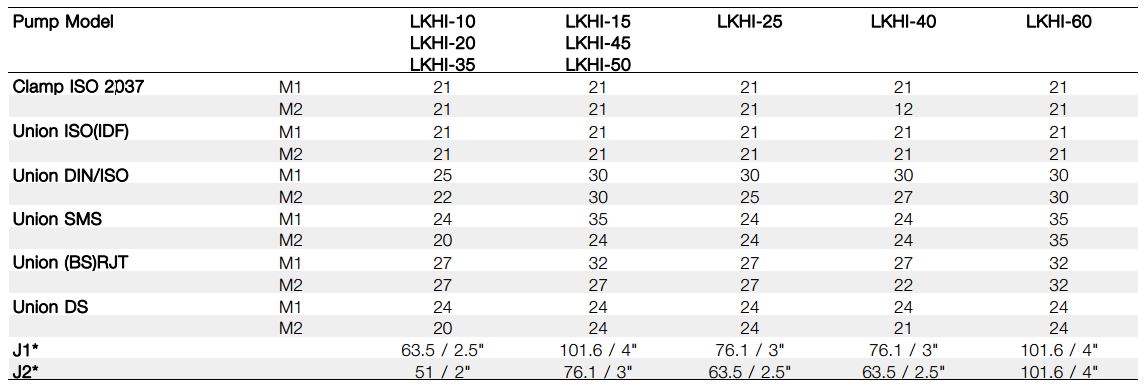

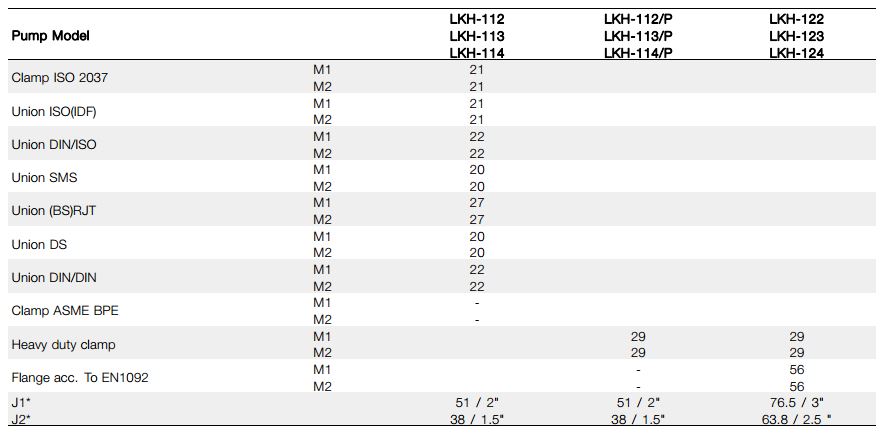

Connections

* Other dimensions available on request.

Options

A. Motor with increased safety/flame proof motor. (only LKH-110)

B. Flushed shaft seal.

C. Impeller with reduced diameter.

D. Product wetted seals of Nitrile (NBR), or Fluorinated rubber (FPM).

E. Rotating seal ring of Silicon Carbide.

Note! For further details, see also instruction manual.

Ordering

Please state the following when ordering:

– If the inlet pressure is higher than 10 bar it is necessary to order a special version with a modified motor and a stronger backplate. For exact specification, please use the Anytime Configurator. Use the following designation:

– LKH-110: Inlet pressure (0-10 bar)

– LKH-110/P: Inlet pressure > 10 bar

– Pump size.

– Version, hygienic or industrial.

– Connections.

– Impeller diameter.

– Motor size.

– Voltage and frequency.

– Flow, pressure and temperature.

– Density and viscosity of the product.

– Options.