Alfa Laval LKH Series Centrifugal Pumps

The LKH pump is a highly efficient and economical centrifugal pump, which meets the requirements of hygienic and gentle product treatment and chemical resistance. LKH is available in thirteen sizes, LKH-5, -10, -15, -20, -25, -35, -40, -45, -50, -60, -70, -85 and -90.

Standard design

The LKH pump is designed for CIP with emphasis on large internal radii and cleanable seals. The hygienic version of LKH has a stainless steel shroud for protection of the motor, and the complete unit is supported on four adjustable stainless steel legs.

Shaft Seals

The LKH pump is equipped with either an external single or a flushed shaft seal. Both have stationary seal rings made from stainless steel AISI 329 with sealing surface in silicon carbide and rotating seal rings in carbon. The secondary seal of the flushed seal is a long lasting lip seal. The pump may also be equipped with a double mechanical shaft seal.

Technical data

Materials

Product wetted steel parts: . . . . . . . . W. 1.4404 (316L)

Other steel parts: . . . . . . . . . . . . . . Stainless steel

Finish: . . . . . . . . . . . . . . . . . . . . . Standard blasted

Product wetted seals: . . . . . . . . . . . EPDM rubber

Connections for FSS and DMSS: 6mm tube/Rp 1/8″

Motor sizes

50 Hz: . . . . . . . . . . . . . . . . . . . . . 0.75 – 110 kW

60 Hz: . . . . . . . . . . . . . . . . . . . . . 0.9 – 125 kW

Motor

Foot-flanged motor according to the IEC metric standard, 2 poles = 3000/3600 rpm at 50/60 Hz, 4 poles = 1500/1800 rpm at 50/60 Hz, IP 55 (with drain hole with labyrinth plug), insulation class F.

Min/max motor speed:

2 poles: 0,75 – 45 kW . . . . . . . . . . . 900 – 4000 rpm

2 poles: 55 – 110 kW . . . . . . . . . . . 900 – 3600 rpm

4 poles: 0,75 – 75 kW . . . . . . . . . . . 900 – 2200 rpm

Warranty: Extended 3-years warranty on LKH pumps. The warranty covers all non wear parts on the condition that genuine Alfa Laval Spare Parts are used.

Operating Data

Pressure

Max. inlet pressure:

LKH-5: . . . . . . . . . . . . . . . . . . . . 600 kPa (6 bar)

LKH-10 – 70: . . . . . . . . . . . . . . . . 1000kPa (10 bar)

LKH-70: 60Hz . . . . . . . . . . . . . . . . 500kPa (5 bar)

LKH-85 – 90: . . . . . . . . . . . . . . . . 500kPa (5 bar)

Temperature

Temperature range: . . . . . . . . . . . . . -10°C to +140°C (EPDM)

Flushed shaft seal:

Water pressure inlet: . . . . . . . . . . . . Max. 1 bar

Water consumption: . . . . . . . . . . . . 0.25 -0.5 l/min

Double mechanical shaft seal:

Water pressure inlet, LKH-5 to -60: . . . Max. 500 kPa (5 bar)

Water pressure inlet, LKH-70 and -90: Max. 300 kPa (3 bar)

Water consumption: . . . . . . . . . . . . 0.25 -0.5 l/min.

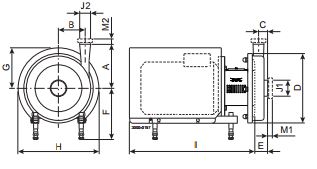

Frequency: 50 Hz Speed (synchr): 3000 rpm Dimensions mm

Flow chart

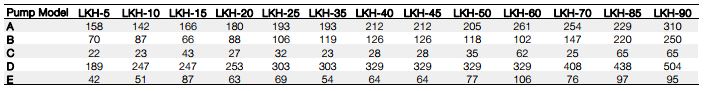

Pump Specific Measures

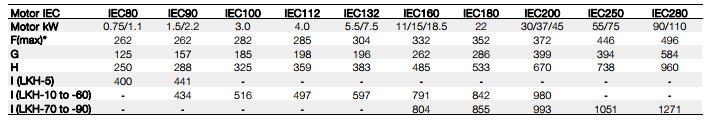

Motor Specific Measures

*Possible to reduce dimension F by min. 59 mm for all pump models. For smaller models it will be possible to reduce dimension F even further.

Motor Overview

From LKH-5 to LKH-85 dimensional data are based on 2 pole, ABB motors.

For LKH-90 dimensional data are based on 4 pole, ABB motors.

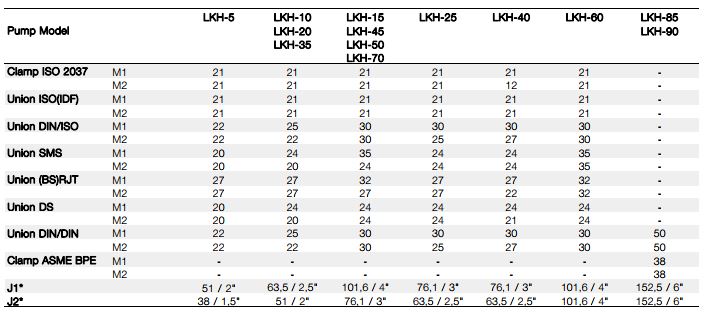

Connections

Keeping you processing

For more information about our products and services please get in touch!

JAMIE WETHERILL

Internal Sales Manager

Call: 01777 712101

Email: jamie.wetherill@moodydirect.com